A Single Zone Variable Air Volume (VAV) system is a specific type of heating, ventilating, and air conditioning (HVAC) system used in open space applications within large facilities and commercial buildings. This system improves space comfort by adjusting both the supply airflow and the discharge air temperature from the air conditioning unit to meet the specific requirements of the space load.

Variable Air Volume (VAV) System Applications

Variable air volume (VAV) systems represent the evolution of constant air volume (CAV) and variable volume and temperature (VVT) systems. VAV systems not only ensure high levels of space comfort but also maintain superior efficiency compared to other HVAC solutions, making them ideal for medium-sized and large commercial buildings.

The increasing market share of VAV systems in the HVAC industry can be attributed to the rapid development and affordability of variable frequency drives (VFDs), a core component of the system.

VAV system applications can be broadly categorized into two types:

- Single Zone VAV Systems

- Multi-Zone VAV Systems

In the remainder of this article, we will dig into the details of single-zone variable air volume applications.

Single Zone Variable Air Volume (VAV) System

Variable air volume systems are utilized in single-zone and open-space HVAC applications, including restaurants, auditoriums, stadiums, airports, fitness centers, warehouses, data centers, and open office spaces, among others.

VAV systems excel in precision and efficiency when delivering space comfort. They can accurately match space loads under almost any condition while adjusting the power consumption accordingly. This adaptability makes these systems highly suitable for applications where the space load experiences significant variations throughout the day.

Single Zone VAV System Components

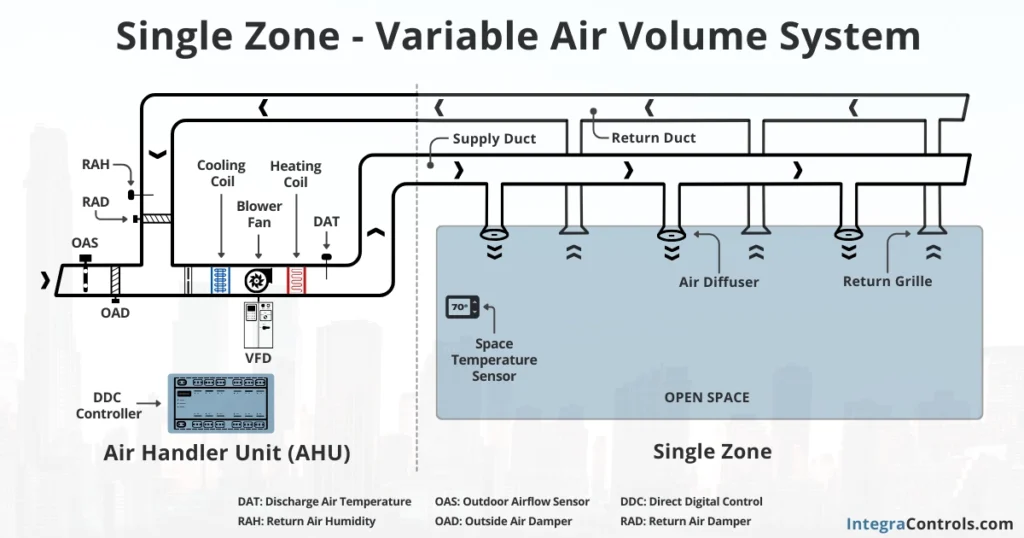

In single-zone applications, VAV systems consist of the following mechanical components: an air handling unit (AHU) with a cooling coil (compressor or chilled water), a heating coil (electric or hot water), a blower fan, and an inverter-duty motor driven by a variable frequency drive (VFD). The VFD is the component that enables the variable airflow characteristic of the system.

Air is distributed through supply and return ducts, although plenum air return applications are also common. Motorized dampers for outside air and return air are used to control the outdoor air intake of the unit. Finally, air is delivered into the space through air diffusers.

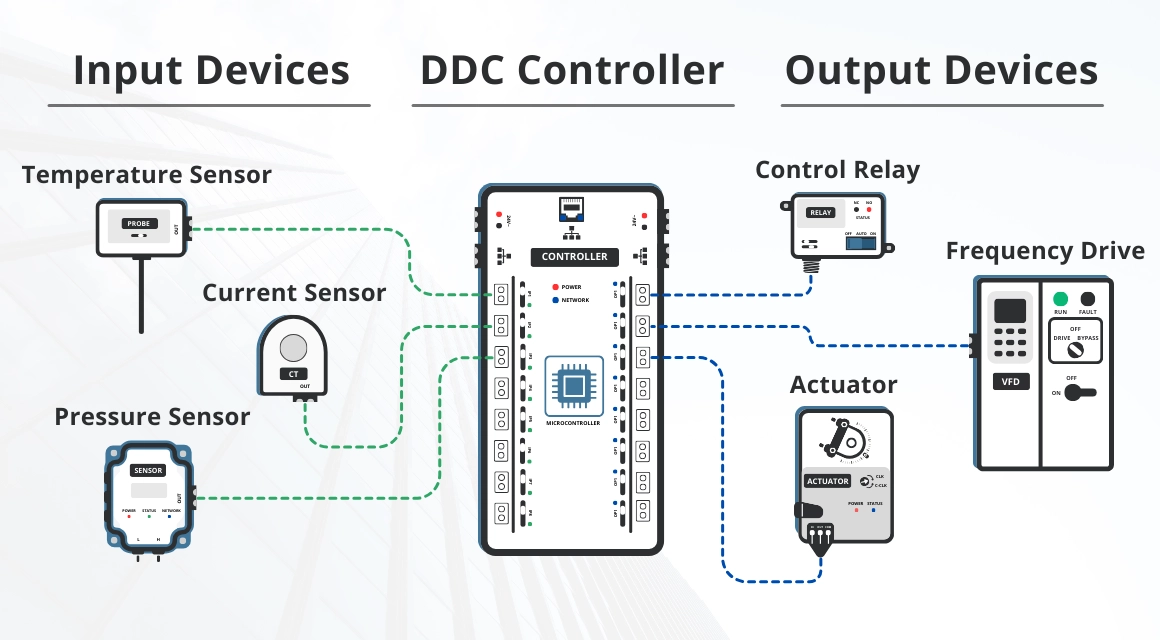

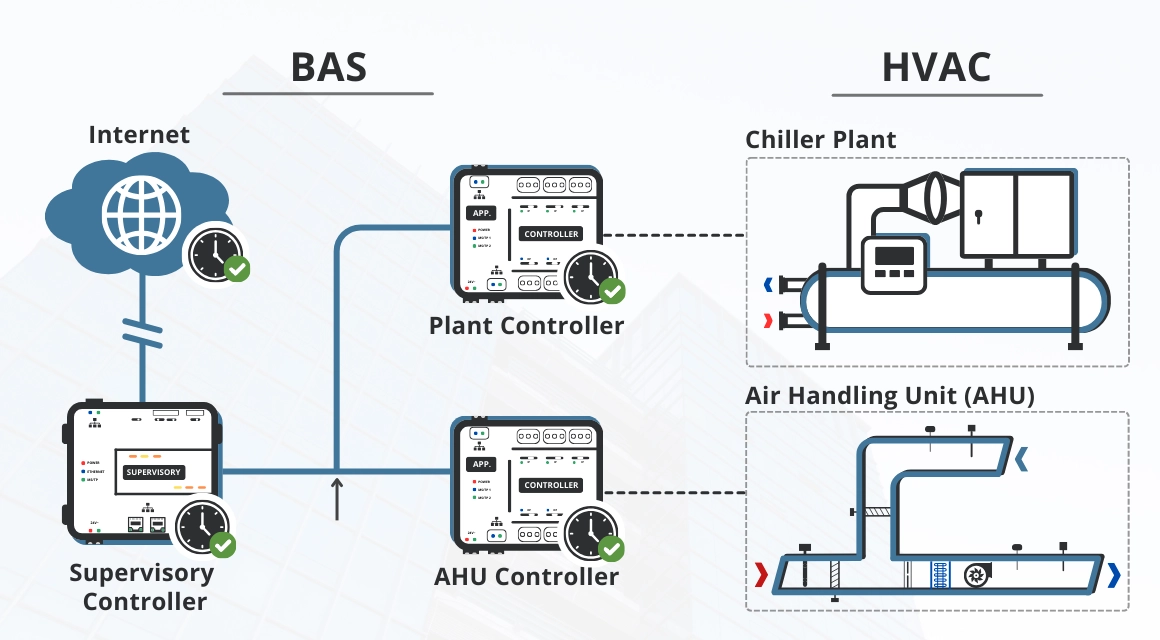

Unit control can be provided by a space thermostat specifically designed for the unit. However, it is more common to use a direct digital control (DDC) controller to handle control duties. This approach offers greater flexibility in setting up the system sequence of operation and allows for additional monitoring and fault detection capabilities.

Single Zone VAV System Operation

To ensure proper space comfort, a single-zone variable air volume system must control three main variables: space temperature, space humidity, and outdoor air intake.

Control of these variables is achieved through a sequence of operation and control strategies that monitor and act on the different mechanical components of the system to adjust the air conditions toward the desired setpoints.

In the following points, we will cover temperature and humidity control and address outdoor air intake control as a separate topic (ventilation) due to its particular importance.

Single Zone VAV System Temperature Control

Two main variables can influence space temperature: discharge air temperature and air volume rate. A single-zone VAV system controls space temperature by varying both of these variables.

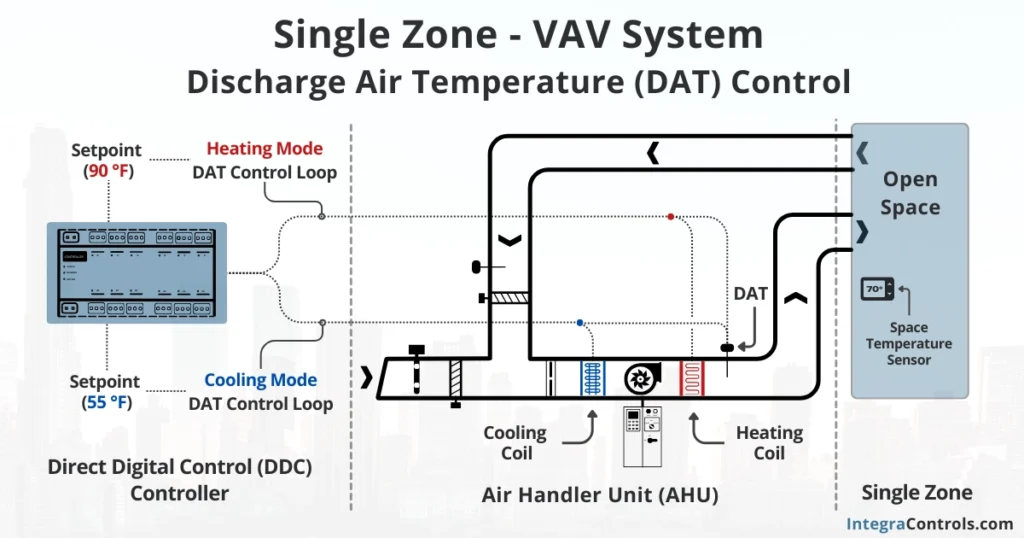

Discharge Air Temperature Control

The discharge air temperature is a controlled parameter within the system. As long as space humidity levels are within the proper range, the unit is designed to maintain a discharge air temperature (e.g., 55 °F) below the space setpoint (e.g., 70 °F) when the system is in cooling mode. In this scenario, the unit directs the cooling coil to operate while keeping the heating coil inactive.

Conversely, when the system is in heating mode, the unit maintains a discharge air temperature (e.g., 90 °F) above the space setpoint (e.g., 70 °F). In this mode, the unit commands the heating coil to operate while ensuring the cooling coil remains inactive.

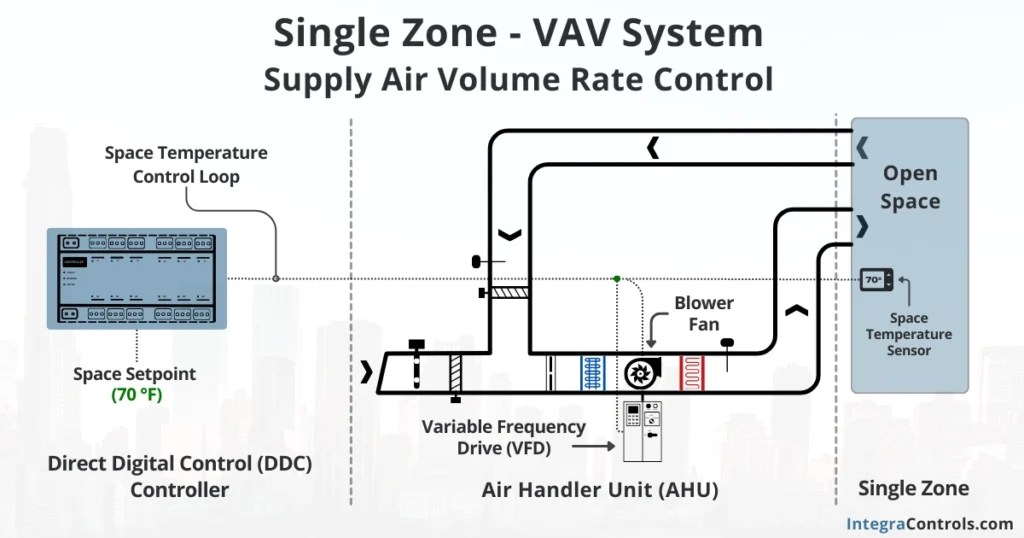

Supply Air Volume Rate Control

The system’s supply airflow is adjusted to reach the space setpoint. The supply air volume rate varies through a control loop established between the actual space temperature and the setpoint. The output of this control loop governs the speed of the blower fan via the variable frequency drive.

In simpler terms, the blower fan’s speed modulates between a minimum and a maximum speed. For example, in cooling mode, if the space temperature falls below the desired setpoint, the fan speed decreases until it reaches the minimum speed. On the contrary, if the space temperature surpasses the setpoint, the fan speed increases until it reaches the maximum speed.

The maximum speed typically corresponds to the motor’s full speed, while the minimum speed is restricted in the VFD settings and the DDC controller. This limitation ensures compliance with ventilation requirements and prevents compressor damage due to slugging.

Single Zone VAV System Humidity Control

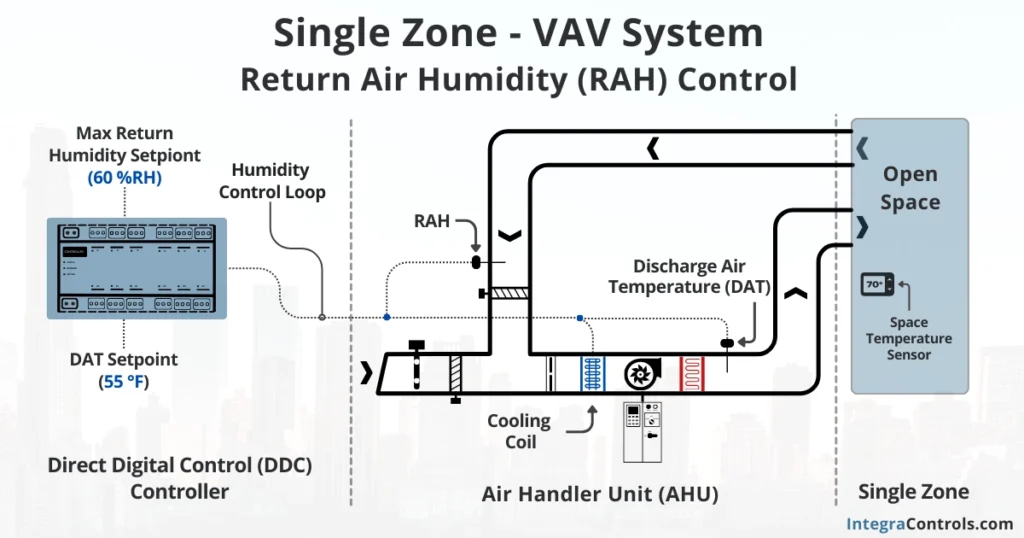

Space relative humidity should be maintained within acceptable comfort levels (e.g., 30% RH – 60% RH). The relative humidity of the space is closely linked to outdoor air humidity unless the nature of the space application involves the production of water vapor as part of the business operation.

This correlation between outdoor air humidity and space humidity needs to be counteracted by dehumidifying the air. An air conditioning system achieves this by promoting condensation. This process involves passing the air through a cold surface, such as a cooling coil surface at 45 °F.

During cooling seasons, when outdoor air humidity is high, the discharge air temperature should be at 55 °F or below to sustain proper indoor relative humidity levels. Conversely, in the heating season, if outdoor humidity levels are acceptable, the discharge air can be adjusted higher or lower based on the space load. This process, known as passive dehumidification, involves the constant dehumidification of air as part of normal system operation.

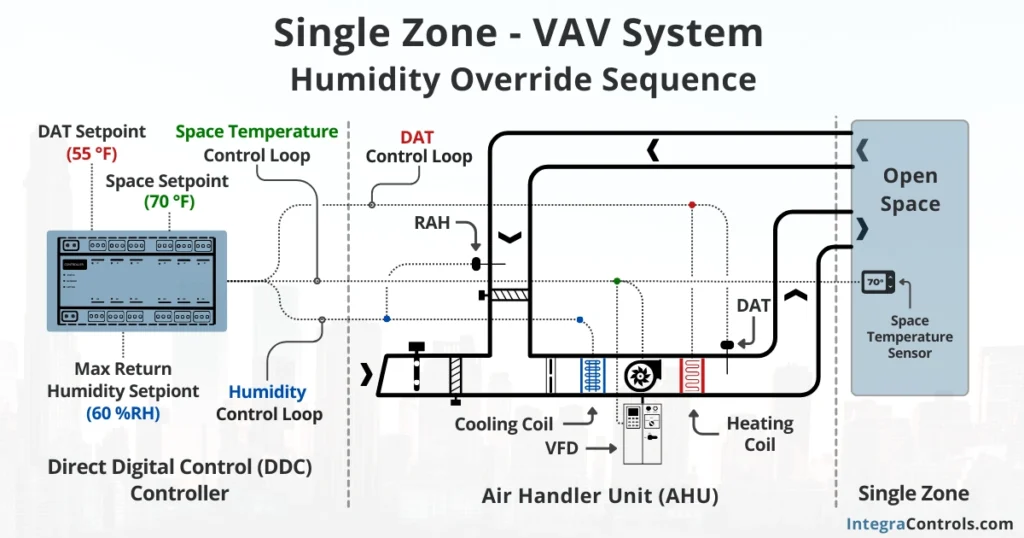

Humidity Override Sequence

When the unit is unable to remove all the humidity from the space, it shall initiate an override sequence that resets the discharge air to a lower temperature. This adjustment increases air condensation, thereby reducing the relative humidity.

During a dehumidifying override sequence, the unit must continue to control space temperature. This is achieved by simultaneously operating both the cooling coil to manage humidity and the heating coil to control discharge air, along with adjusting the fan speed to regulate space temperature.

Dehumidifying override sequences should not occur frequently, as the unit is designed to passively control humidity. If this sequence runs continuously, there may be other factors contributing to elevated humidity levels that require consideration, such as unit maintenance, higher-than-expected outdoor air intake, building negative pressurization, air balance issues, sensor calibration problems, etc. In such cases, the unit should be inspected by a commissioning agent who can verify the system’s operation and ensure it is functioning as intended.

Single Zone VAV System Ventilation

Ventilation is a critical component that significantly contributes to indoor air quality (IAQ). However, it is often overlooked, which is why we have chosen to address it separately in this article.

According to ASHRAE®, ventilation air is defined as that portion of supply air consisting of outdoor air plus any recirculated air that has been treated to maintain acceptable IAQ.

Acceptable indoor air quality (IAQ), per ASHRAE®, is air in which there are no known contaminants at harmful concentrations, as determined by relevant authorities, and with which a substantial majority (80% or more) of the people exposed do not express dissatisfaction.

Single Zone VAV System Ventilation Standard

The ventilation air distribution system for a single-zone variable air volume (VAV) application shall be equipped with means to adjust the system to achieve at least the minimum ventilation airflow required by Section 6 of ASHRAE® Standard 62.1 under any load condition or dynamic reset condition.

ASHRAE® Standard 62.1 specifies minimum ventilation rates and other measures designed to ensure indoor air quality (IAQ) that is acceptable to human occupants and minimizes adverse health effects.

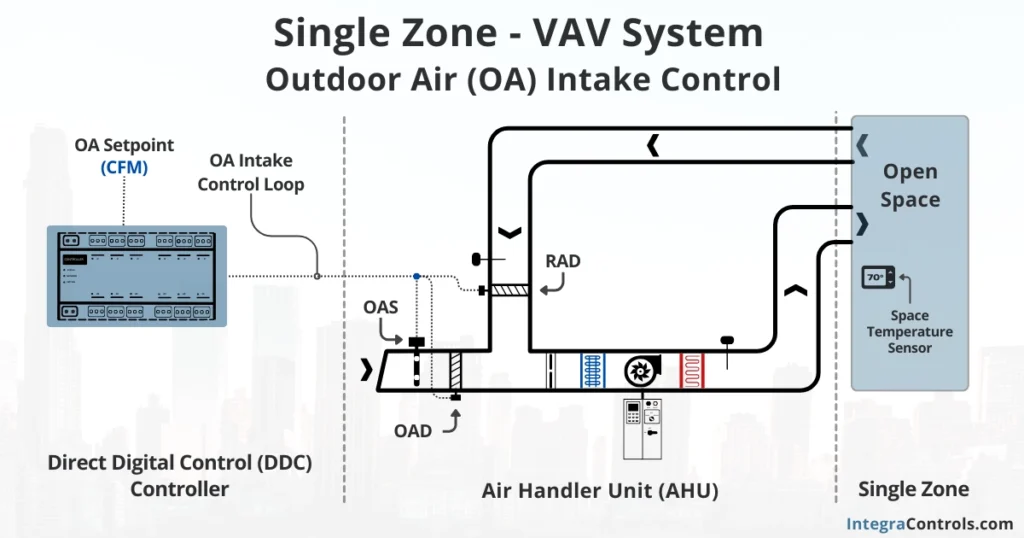

Single Zone VAV System Ventilation Control

In a single-zone VAV system, three main control mechanisms must be established and controlled to maintain the minimum ventilation rates specified by ASHRAE®:

Minimum Blower Fan Speed: The variable frequency drive minimum speed should not be set lower than the minimum speed that allows the designed minimum ventilation rate under any load condition.

Outdoor Air Damper (OAD) Control: The outdoor air damper should modulate to maintain the designed minimum ventilation rate under any load condition.

Return Air Damper (RAD) Control: If the outdoor air damper is fully open and the designed minimum ventilation rate has not been met, the return air damper should close until a minimum setpoint (e.g., 30%) is reached. This action helps the system achieve the desired outdoor airflow setpoint.

Single Zone VAV System Ventilation Reset

The outdoor air intake can be reset to improve the overall efficiency of the unit during periods of lower occupancy in the space. To capitalize on these sequences, an occupancy estimating mechanism, such as CO2 sensors, must be in place.

The minimum outdoor air intake specified by ASHRAE® consists of two main components that constitute the required outdoor intake rate. One is dependent on the area of the space served, and therefore remains constant, while the other is correlated with the occupancy in the space or the number of people occupying it.

With an occupancy estimating mechanism, the required outdoor intake rate can be reset lower, significantly improving the unit’s efficiency. This reset mechanism is commonly referred to as demand-controlled ventilation (DCV).

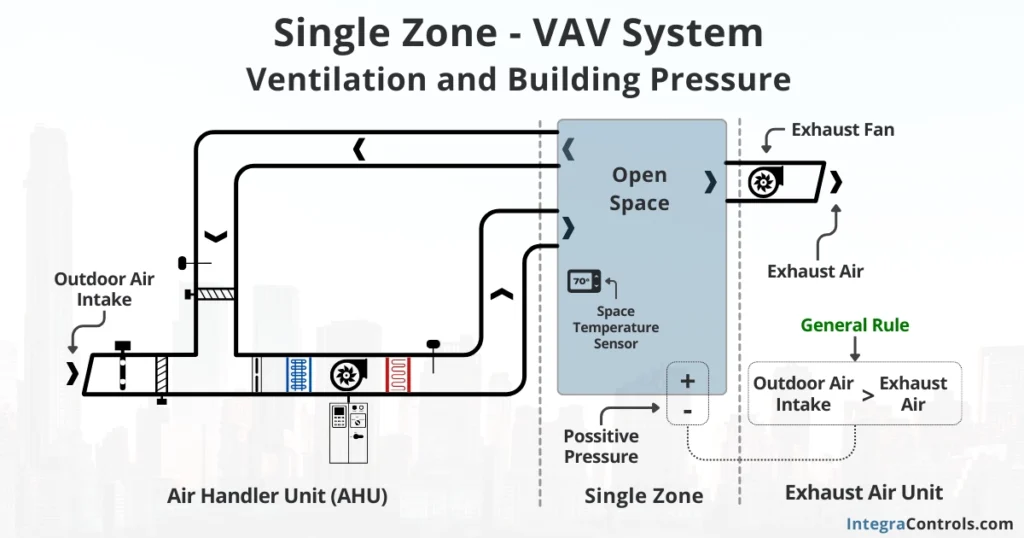

Ventilation and Building Pressure

Another crucial factor to consider when controlling outdoor air intake is building pressure. The overall building pressure is determined by the combination of exhaust air and outdoor air intake.

The general rule specified by ASHRAE® is that the total building outdoor air intake should equal or exceed the total building exhaust under all load and dynamic reset conditions. This ensures that the overall building pressure remains positive, preventing the infiltration of untreated outdoor air.

This point is sometimes overlooked in building management operations. Frequently, the outdoor air intake of the air handling units is incorrectly shut down in an attempt to “mitigate” space load demand. Operators do this without realizing that they are violating ventilation requirements and without understanding the detrimental consequences of negative building pressurization, such as elevated humidity and CO2 levels.

Single Zone CAV, VVT, and VAV Comparison

Despite the well-known efficiency of variable air systems compared to other HVAC systems, constant air volume systems are still used in many instances. This is because efficiency is just one of the factors engineers consider when choosing an HVAC application. Other factors, such as system cost, control complexity, and expected comfort, must also be considered to make a more cost-effective selection.

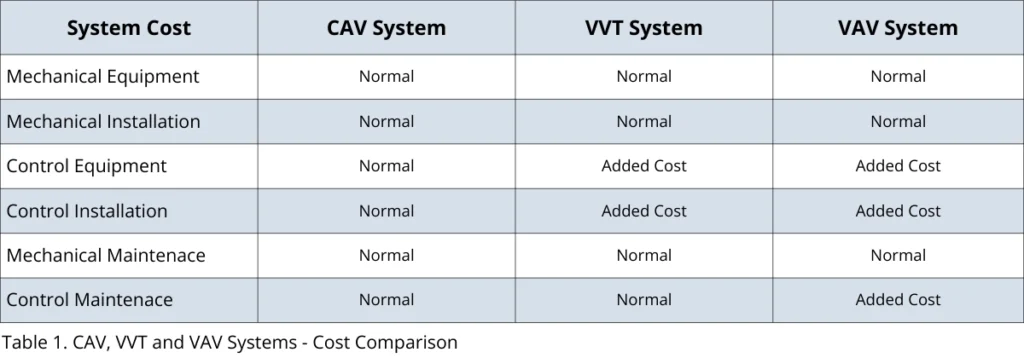

System Cost

The total HVAC system cost can be categorized into the following main components:

- Mechanical equipment and installation cost

- Control equipment and installation cost

- Maintenance cost

Mechanical Equipment and Installation Cost

The costs associated with mechanical equipment, furnishing, and installation do not vary significantly among CAV, VVT, and VAV systems. The only additional mechanical components in the VVT system, compared to the CAV system, are a bypass duct, control motorized damper, and actuator.

Similarly, the primary distinction between the CAV and VAV systems is the addition of the variable frequency drive (VFD) cost in the VAV system. In some cases, replacing the blower fan motor with an inverter-duty motor may be necessary, incurring additional costs, especially if it is a large motor.

In general, the mechanical investment for a single-zone application is not substantially different when comparing the three systems (CAV, VVT, and VAV).

Control Equipment and Installation Cost

The costs associated with control equipment, furnishing, and installation differ between CAV, VVT and VAV systems. In single-zone applications, CAV systems often rely on a standard thermostat for control, while VVT and VAV systems typically require Direct Digital Control (DDC) systems. This distinction significantly impacts the implementation cost of these systems when compared to the CAV system.

The additional cost arising from control complexity in VVT and VAV systems is one of the reasons why CAV systems remain highly popular for single-zone applications, despite being less efficient than variable air volume solutions.

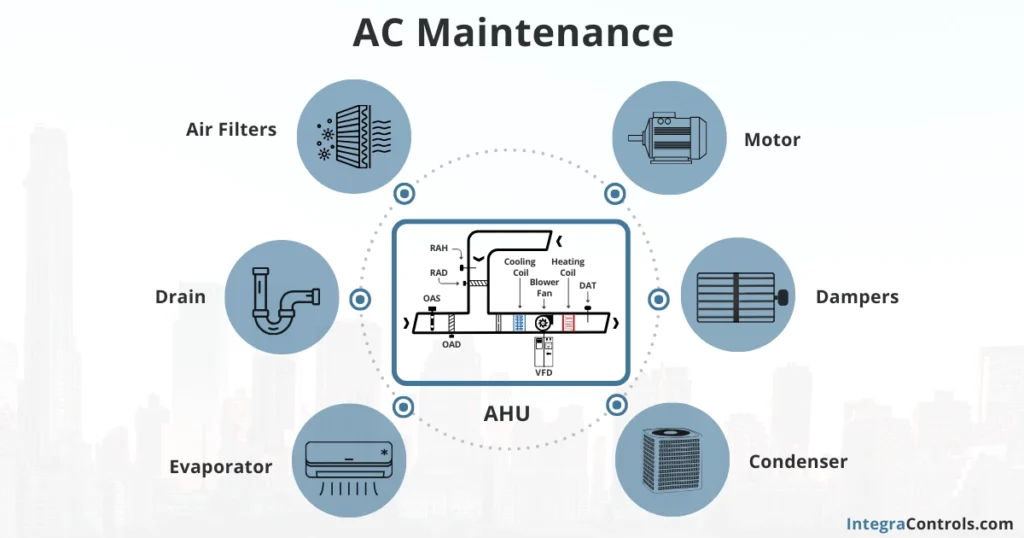

Maintenance Cost

The maintenance cost associated with implementing one system over another does not vary significantly from a mechanical standpoint. Regardless of the system, regular tasks such as replacing air filters, cleaning evaporator and condenser coils, treating and flushing the drainage system, replacing blower fan belts, and inspecting outdoor air intake dampers are necessary.

Differences in maintenance costs arise from a control standpoint. The major distinction lies in the VAV system compared to CAV and VVT systems, primarily due to the added outdoor air ventilation control in VAV systems.

Ventilation control in VAV systems requires regular testing and calibration to ensure it functions as intended. This involves exercising the outdoor and return air dampers, as well as cleaning and calibrating the outdoor airflow sensor for accurate readings, as these sensors tend to accumulate dirt over time.

Table 1. shows the system cost comparison among the CAV, VVT and VAV systems.

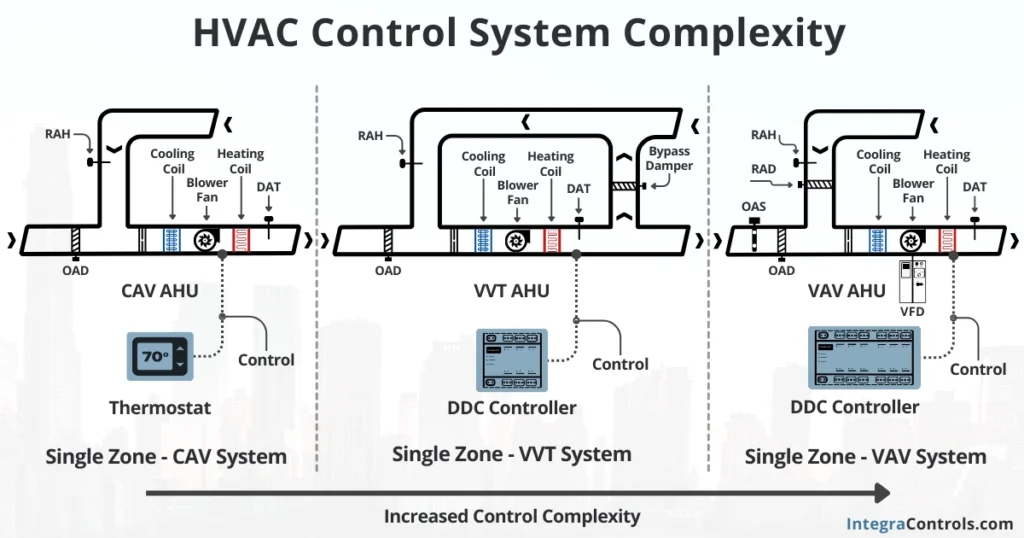

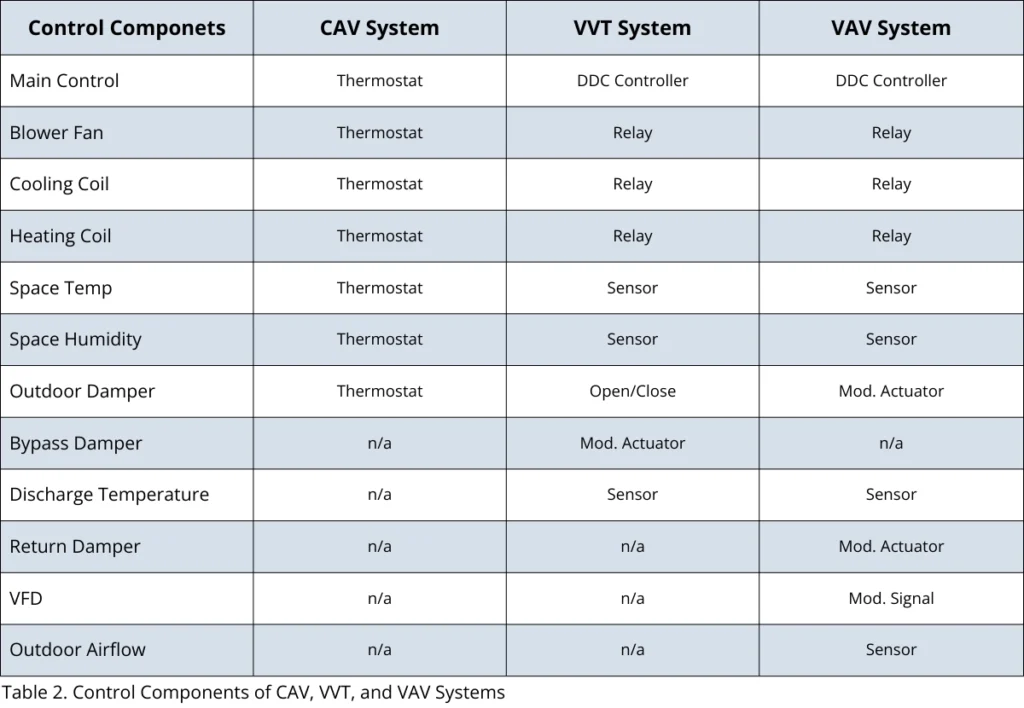

Control Complexity

Achieving higher levels of efficiency in HVAC system performance often involves a trade-off, typically in the form of increased cost or additional system complexity.

When transitioning from a CAV system to a VVT or VAV system, there is an added layer of system control complexity that must be considered when selecting the application. This is crucial because this additional control complexity comes with an associated cost, as previously mentioned, encompassing added control equipment furnishing, installation, and maintenance. Additionally, one should take into account potential future service calls and equipment troubleshooting costs.

To better show the added control complexity of each of these systems (CAV, VVT, and VAV), we have provided a comprehensive breakdown of their main control components in Table 2. For the purpose of this example, we consider the cooling coil source as compressors and the heating coil as an electric duct heater.

Table 2 clearly illustrates the added control complexities of each system when compared with each other. It is evident that the CAV system is the simplest among these HVAC systems, enabling control from a single device such as a thermostat. Consequently, CAV systems do not incur additional costs associated with the implementation of DDC controllers and more complex control strategies. It is no surprise that constant air volume systems remain a viable and widely used solution for single-zone applications.

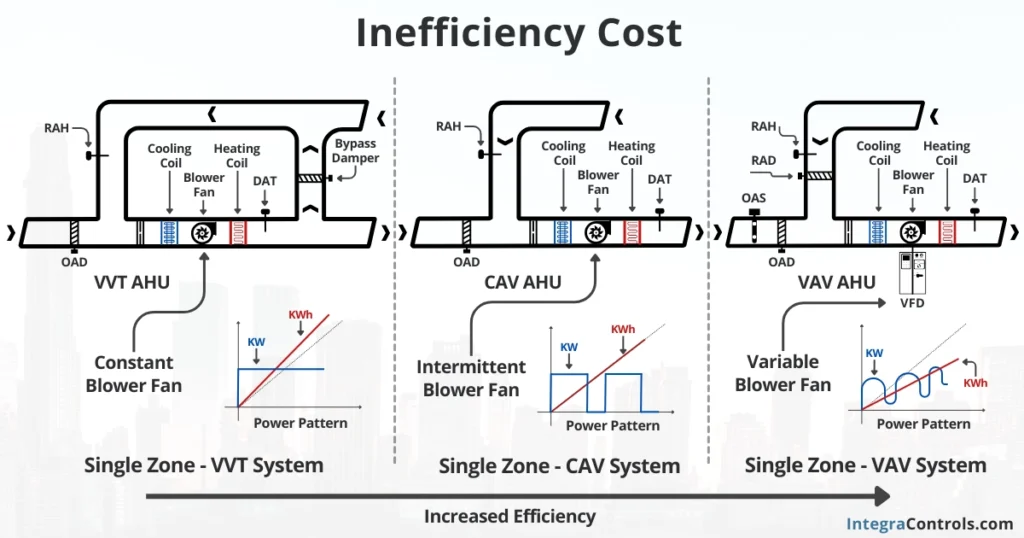

Inefficiency Cost

Inefficiency cost refers to the differential cost incurred throughout the entire equipment lifespan due to inefficiencies when compared to a more efficient solution.

VAV systems demonstrate greater efficiency than CAV and VVT systems. The primary reason for this enhanced efficiency lies in the lower power consumption of the blower fan motor during low-load conditions, facilitated by the inclusion of a variable frequency drive.

Both CAV and VVT systems inherently carry an inefficiency cost when compared to VAV systems. In these systems, the blower fan motor consistently operates at the same speed for any load condition, resulting in extra power consumption, which becomes an inefficiency cost over the entire equipment lifespan.

However, when comparing CAV to VVT systems, there is no definitive improvement in efficiency. In fact, CAV systems can consume less power and, therefore, be more efficient than VVT systems under similar conditions. The primary reason for this lies in the discharge air temperature control in VVT systems, where the cooling coil operates continuously to maintain a constant discharge air temperature (e.g., 55 °F) for passive dehumidification. Additionally, the blower fan in VVT systems never stops even when the space setpoint is met. In contrast, a CAV system’s blower fan can operate intermittently, shutting down both the fan and cooling stages when the space setpoint is reached and restarting when needed.

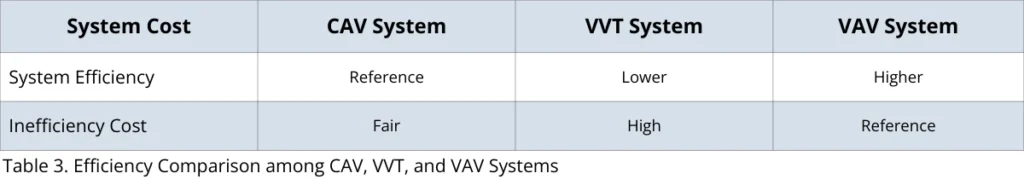

Table 3 provides a comparison among the three systems (CAV, VVT, and VAV) regarding their efficiency, using the CAV system as a point of reference. We have also included the inefficiency cost using the VAV system as a point of efficiency reference.

We observe that VVT systems are not an efficient solution for single-zone applications, as they are less efficient than the CAV system while having a higher implementation cost, as discussed earlier. Fairly enough, VVT systems are rarely seen in single-zone applications. The added space comfort, as we will discuss next, does not compensate for the extra cost associated with their implementation.

Comfort Expected

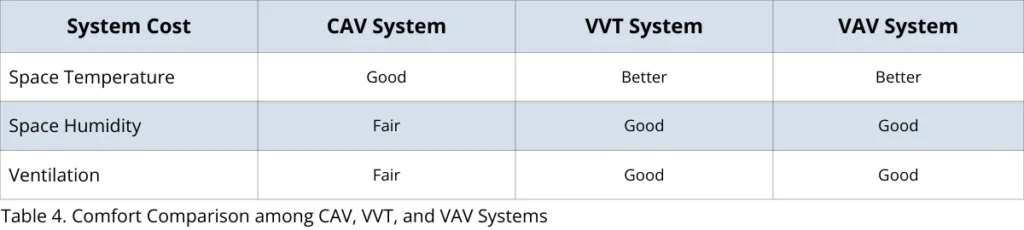

The primary goal of implementing an HVAC application is to provide cost-effective space comfort. Having discussed the cost and efficiency factors in CAV, VVT, and VAV systems, let’s now explore the space comfort aspects for these single-zone applications.

If we define space comfort as temperature, humidity, and ventilation levels that are comfortable for most occupants, we can say then that all single-zone CAV, VVT, and VAV systems achieve acceptable levels of space comfort. However, it’s crucial to note that CAV systems often work intermittently, impacting space comfort.

When a CAV system reaches the desired space temperature, the blower fan and cooling coils cease operation until the thermostat signals the need for cooling again. This interruption affects humidity and ventilation control, as ventilation is halted during this period. Additionally, relative humidity may temporarily increase when the system restarts. The cycling of the CAV system is undesirable as it can wear out compressors and create discomfort for occupants. Engineers address this by carefully selecting the appropriate unit capacity for the application.

Table 4 provides a comparison among the three systems (CAV, VVT, and VAV) considering the comfort factors discussed earlier.

In Summary

Single zone variable air volume (VAV) systems are specialized HVAC systems designed for open-space applications in large commercial buildings. These systems improve space comfort by adjusting both supply airflow and discharge air temperature based on the space cooling or heating load demand. The VAV system, particularly in single-zone applications, proves to be an advanced and efficient solution, surpassing constant air volume (CAV) and variable volume and temperature (VVT) systems in terms of performance and adaptability.