Challenge

HVAC failures occur repeatedly and unexpectedly, causing recurrent business interruptions.

The healthcare provider has been impacted by frequent and unexpected HVAC failures over the past three years, often resorting to renting portable air conditioning units to combat the high temperatures in South Florida, incurring significant expenses in the process.

Despite consistent equipment maintenance, service calls, and repairs, problems persist and have become more frequent in recent months, prompting the need to identify the root cause and proactively address these issues.

Scope of Work

The audit encompasses a thorough examination of the entire HVAC control system within the healthcare facility. This includes identifying malfunctioning and incomplete sequences of operations, pinpointing critical and inadequately commissioned components, and uncovering potential fault detection indicators that can alert building operators through the Building Management System (BMS) when equipment failures are imminent.

HVAC systems subject to the control audit:

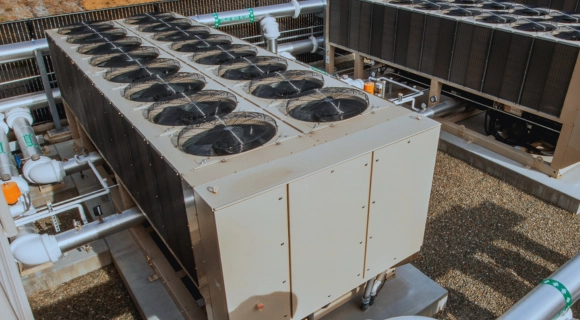

- Seven Rooftop Units (Single Zone – Constant Air Volume – DX)

- Two Split Systems (Single Zone – Constant Air Volume – DX)

Audit Summary

Total Equipment Audited

Incomplete Sequences Detected

Equipment Deterioration Factors

Energy Waste Sources Identified

Fault Detection Possibilities

Non-Commissioned Components

While most HVAC control devices maintain adequate space temperature levels, many sequences of operations are incomplete and could benefit from optimization for enhanced control and efficiency.

Numerous control points require verification and commissioning. Additionally, there is a lack of indicators for monitoring air quality factors such as humidity, carbon dioxide levels, and exhaust air control within the building automation system.

Several critical issues were identified that could contribute to shortened equipment lifespans, premature failures, and energy inefficiencies.

Critical Items

- Some units operate continuously, resulting in energy waste during unoccupied hours.

- Two units have short-cycling compressors, which can lead to premature failure.

- Most units show imbalanced compressor runtimes, which could shorten the lifespan of components and equipment.

- A unit exhibits a 4°F space control temperature offset, indicating potential issues such as impending failure, maintenance deficiencies, or duct problems.

Recommendations

- Recommission units and complete their sequence of operations.

- Conduct indoor air quality (IAQ) testing and integrate ventilation control mechanisms.

- Address short-cycling compressors and implement runtime management sequences.

- Implement fault detection mechanisms to anticipate and prevent future failures.