A constant air volume (CAV) system is a type of heating, ventilating, and air conditioning (HVAC) system. A CAV system ensures space comfort by adjusting the discharge air temperature of the air conditioning unit according to the space load while maintaining a constant airflow supply.

Types of Constant Air Volume (CAV) Systems

There are three main types of CAV systems:

- Single Duct System

- Terminal Reheat System

- Mixed Air System

Single Duct System

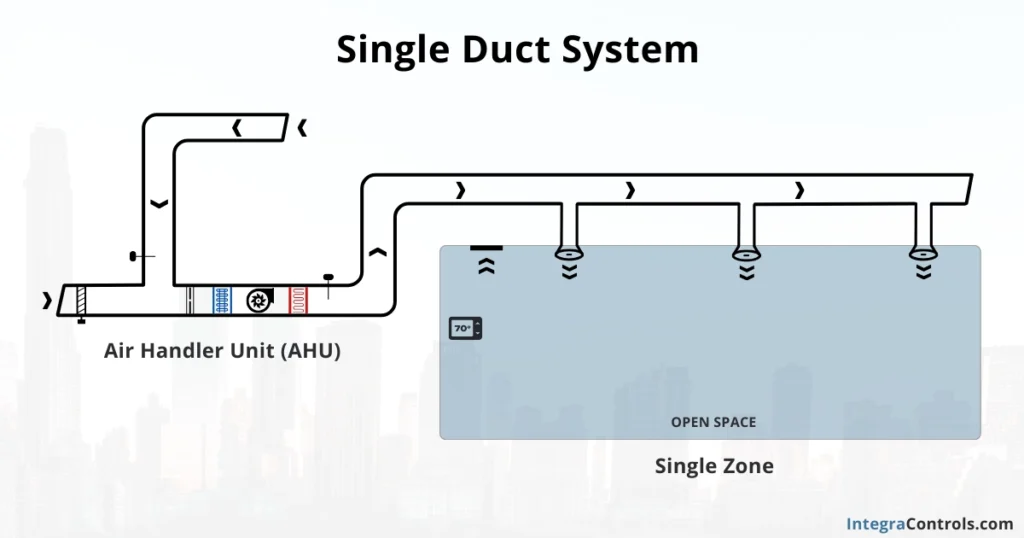

A single duct system is a constant air volume (CAV) application consisting of an HVAC unit, a main supply duct, and a controlling device, such as a thermostat. Single duct systems are primarily used in open spaces and dedicated single-zone applications, such as warehouses, restaurants, and residential settings.

This CAV system is effective for single-zone applications where the space heat load remains relatively constant and close to the air conditioning capacity. However, it is not recommended for multi-zone applications, as this system cannot deliver proper space comfort for specific rooms. In such cases, a terminal reheat system may be a more suitable alternative.

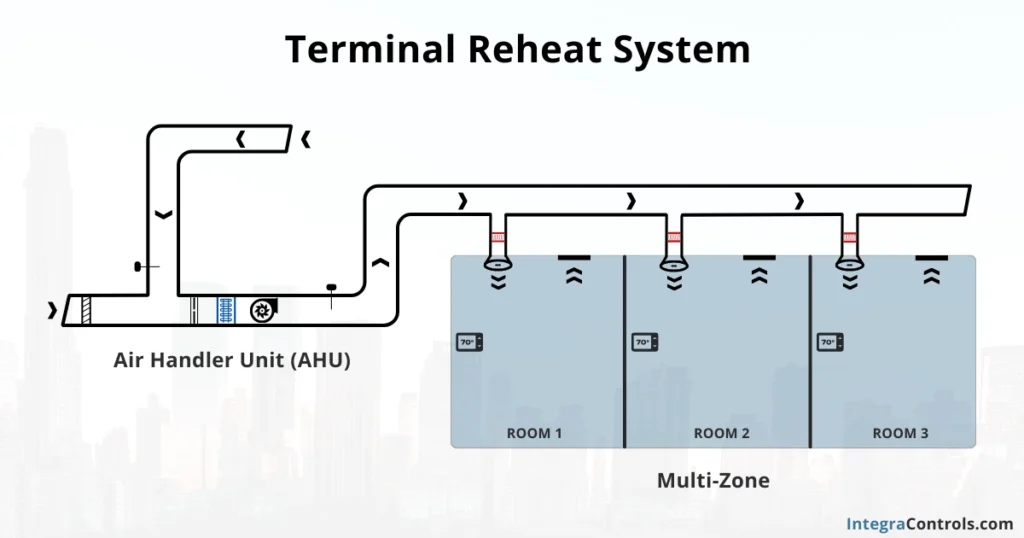

Terminal Reheat System

A terminal reheat system is similar to the single duct system, with the addition of a heat source component, such as a duct heater or hot water coil. This heat source terminal is typically installed in each supply duct branch, serving a dedicated room. It also comes with a thermostat that controls its operation. Terminal reheat systems are suitable for multi-zone applications, such as gyms with locker rooms and offices, where the space load is not constant or evenly distributed across rooms.

Despite their suitability for multi-zone applications, terminal reheat systems are not very efficient. The heat source needs to warm the air that was previously cooled down by the air conditioning unit, leading to continuous energy waste as a trade-off for space comfort.

To improve the efficiency of the constant air volume system when used for multi-zone applications, the mixed air system was conceived.

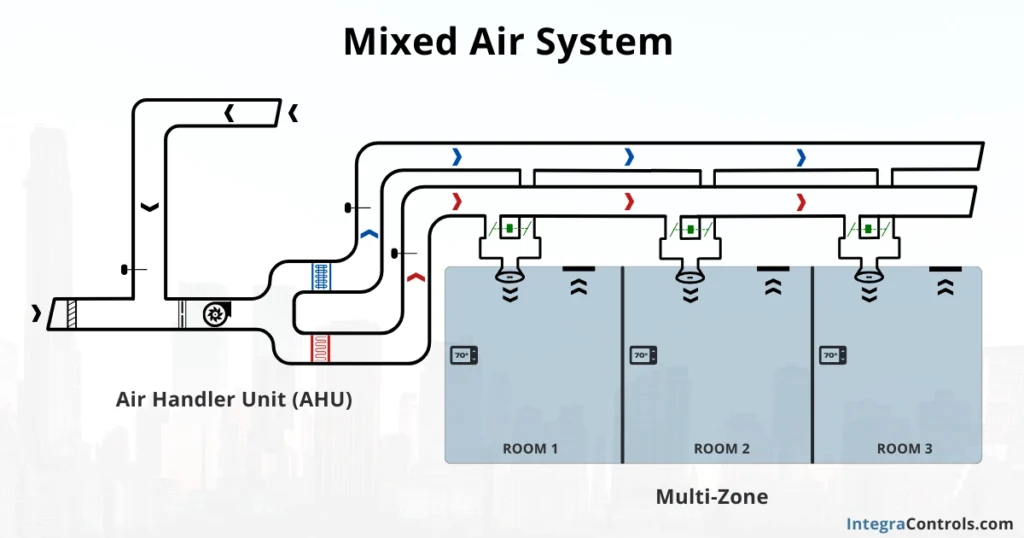

Mixed Air System

A mixed air system is a variation of the terminal reheat system. Instead of using a heat source in every single duct terminal, this CAV system employs two main supply air ducts, one providing cold air and the other supplying hot air. A combination of these two air streams balances the space heat load through a mixing air box, which is a dedicated terminal unit serving each room and controlled by a thermostat. Mixed air systems are used in multi-zone applications where space comfort is crucial, such as in office buildings and schools.

Mixed air systems are not particularly efficient applications, as they need to provide both cold and hot constant air streams at all times. Nevertheless, this inherent inefficiency can be improved through discharge temperature reset control sequences. Despite achieving good space temperature control, mixed air systems do not guarantee proper space humidity levels.

Currently, mixed air systems are not commonly seen applications, as variable air volume systems are becoming the standard for multi-zone applications due to their increased affordability and higher efficiency.

CAV Systems: Components and Operation

The different types of constant air volume systems operate under the same basic principle of maintaining a constant stream of air while changing the discharge air temperature. However, the mechanical and control components vary for each of these systems, as well as their sequence of operation.

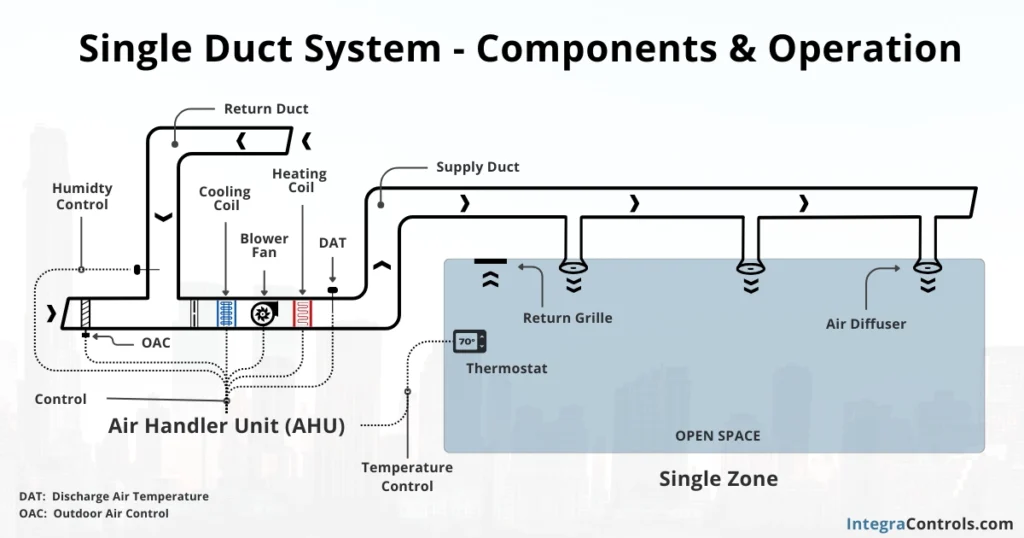

Single Duct System: Components

The single duct system is the least complex of all constant air volume applications. The system consists of an air handling unit (AHU), primarily composed of a cooling coil (compressor or chilled water), a heating coil (electric or hot water), and a constant speed blower fan wheel and motor. Supply and return ducts are used for air distribution, and the air is provided into the space through air diffusers.

The system’s control can be provided by a thermostat, which can be installed inside the space or in the return duct. This thermostat will monitor temperature and, in some cases, relative humidity.

Single Duct System: Sequence of Operation (SOO)

A single duct system is a fairly simple application when it comes to control operation. There are two main controlled variables: space temperature and relative humidity.

Single Duct System: Temperature Control

The unit shall have two main states of operation: cooling and heating. When the unit is in the cooling state, the control shall call for cooling based on the space or return temperature setpoint, while the heating coil remains off. On the other hand, if the unit is in the heating state, the cooling coil shall remain inactive while the control engages the heating coil to heat the space until the desired setpoint is reached.

Single Duct System: Humidity Control

In a single duct system with cooling and heating coils, there is the possibility of having a dehumidifying override sequence to control space relative humidity. In this sequence, the cooling coil is enabled to dehumidify the air through condensation, while the heating coil is used to control space temperature. This is called an override sequence because it overrides the normal unit sequence of operation (SOO).

As mentioned earlier, a single duct system is suitable and still very often used in single-zone and open space applications. However, when temperature control of multiple rooms is required, a constant air volume multi-zone application, such as the terminal reheat system, is a more effective solution.

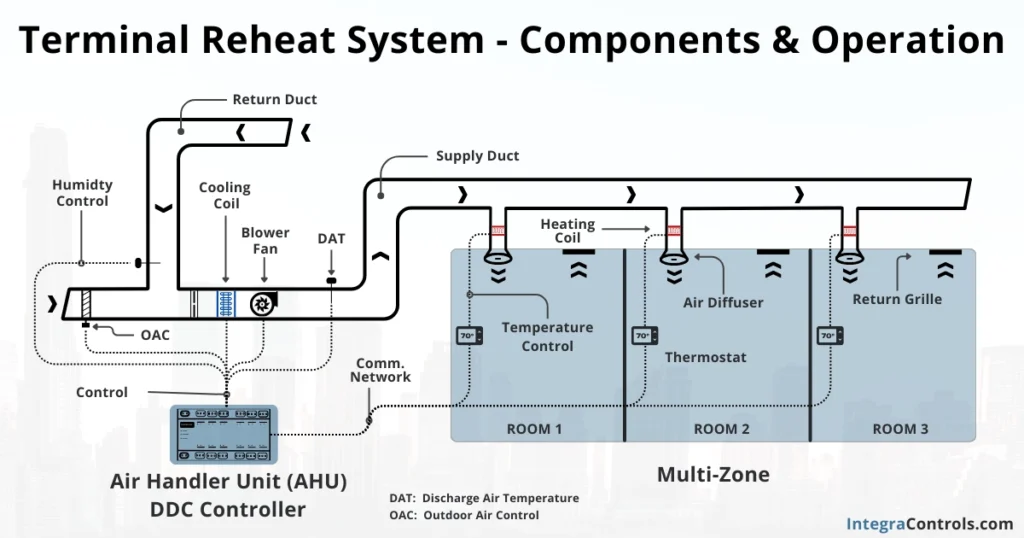

Terminal Reheat System: Components

A terminal reheat system is designed to provide temperature control for multi-zone applications. The system consists of an air handling unit (AHU), a cooling coil (compressor or chilled water), and a constant-speed blower fan wheel and motor. Supply and return ducts are used for air distribution. However, unlike single duct applications, in this system, each supply air branch serving a separate room incorporates a heating device, which can be either an electric duct heater or a hot water coil served by a boiler. Finally, the air is provided into the space through air diffusers.

As mentioned before, a terminal reheat system can provide control for every single room in the space, so each one will have a control device such as a thermostat that will allow for this operation. Also, the main air handling unit (AHU) providing a constant supply of air shall have a control device that will drive the unit’s operation, as we will describe next.

Terminal Reheat System: Sequence of Operation (SOO)

In a terminal reheat system, there are three main variables that shall be controlled: room temperature, room humidity or return humidity, and discharge air temperature.

Terminal Reheat System: Room Temperature Control

In the case of the terminal reheat system, the return air temperature cannot be used to control space temperature. In this system, room temperature is controlled by the individual heating devices serving each room independently. The main air handling unit shall supply a constant flow of air at 55 °F or less at all times. The heating devices shall operate accordingly to maintain the room temperature setpoint; they shall turn on when the room requires heating and turn off when the room requires cooling.

Terminal Reheat System: Humidity Control

Relative humidity is controlled in this system by maintaining the discharge air temperature at 55 °F or below. Very often, the thermostats in the rooms don’t have relative humidity readings, as they cost more than regular ones that only read temperature. Nevertheless, having a return air humidity sensor can help monitor humidity effectively to ensure it is within the proper levels.

As long as the discharge air temperature remains anchored to 55 °F or below, relative humidity should be within range. However, if the return air humidity goes above a desired setpoint, for instance, 65 %RH, the discharge air temperature could be reset lower temporarily to help dehumidify the air. This can be a simple dehumidifying override sequence to always maintain the proper humidity levels.

Terminal Reheat System: Discharge Air Temperature Control

Even though discharge air temperature is not one of the variables that constitute a space comfort factor, such as room temperature and humidity, it plays an important role in the operation of the entire system. The unit shall monitor discharge air temperature and control the cooling device to make sure it remains at 55 °F or below. This way, the unit is always providing cooling, and the heating devices for each room operate to maintain the setpoints. Also, by maintaining the discharge air temperature at 55 °F or below, the unit is dehumidifying the air, ensuring proper humidity levels in the space.

The discharge air temperature can be reset to make the system more efficient. For instance, if the humidity levels are acceptable and the heating devices can’t heat the space to reach setpoint, the discharge air temperature can be reset higher. This will make the heating devices work less and reach setpoint more efficiently. Similarly, the discharge air temperature can also be reset lower if there is more cooling demand in the space or if a dehumidifying sequence is required, as we have already mentioned.

Terminal reheat systems achieve proper space comfort but with a high inefficiency cost associated. Mixed air systems are implemented to improve this inefficiency problem, but they also come with a trade-off, as we will discuss next.

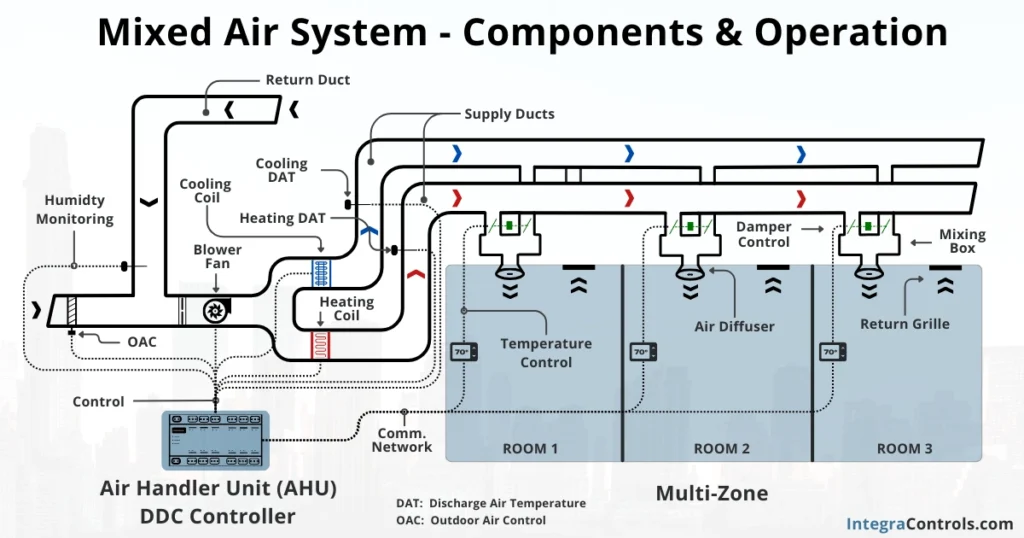

Mixed Air System: Components

Similar to terminal reheat systems, mixed air systems are designed to provide temperature control for multi-zone applications. The system consists of an air handling unit (AHU), a constant-speed blower fan wheel and motor, a return air duct, and two separate supply air ducts. One of the supply ducts has a cooling coil (compressor or chilled water), and the other has a heating coil (electric or hot water). The two ducts get connected to a mixing box serving each room, and a damper controls the air mixture that gets supplied into the space through air diffusers.

As mentioned earlier, this application can provide control for every room in the space. Each mixing box is in charge of controlling the temperature of the room it serves through a control device such as a thermostat. The main air handling unit (AHU), providing a constant supply of air, will also need a control device to drive its operation.

Mixed Air System: Sequence of Operation (SOO)

In a mixed air system, there are three main variables that shall be controlled; these are room temperature, cooling discharge temperature, and heating discharge temperature. Unfortunately, it is not possible to directly control humidity for all space load scenarios.

Mixed Air System: Room Temperature Control

In this system, room temperature is controlled by the individual mixed air boxes serving each room independently. As mentioned earlier, a damper will control the mixture of the two air streams, allowing for more cold air or hot air to pass into the space to meet the desired setpoint.

The damper operation does not vary the duct pressure of the system, as the resulting air mixture will always maintain a constant volume airflow. For instance, the damper can allow 100% cold air and 0% hot air, and in another instance, the mixture can be 70% hot air and 30% cold air; this way, both the air volume and the duct pressure will remain constant.

Mixed Air System: Discharge Air Temperatures Control

In a mixed air system, the dedicated cooling supply duct shall provide constant cold air at all times. The unit controller shall monitor and control the cooling duct discharge air temperature to maintain 55 °F; this value can be reset higher or lower based on the space load.

Similarly, the dedicated heating supply duct shall provide constant hot air at all times. The unit controller shall monitor and control the heating duct discharge air temperature to maintain 75 °F, which can also be reset higher or lower based on the space load.

The mixed air system is very effective in controlling room temperature in multi-zone applications. However, this effectiveness comes with the trade-off of not having humidity control for all space load scenarios. For instance, during cooling seasons, humidity will likely be acceptable as the cooling coil will remove most of it. However, in heating seasons, relative humidity will have little control, potentially leading to air discomfort and other negative consequences of high humidity levels, such as condensation and mold proliferation.

Despite its effective temperature control capabilities, the mixed air system is still an inefficient application, as it has to provide two thermically opposite streams of air at all times and lacks humidity control for all load conditions. This HVAC application is rarely seen nowadays, as variable air volume systems are becoming the standard for multi-zone applications, providing excellent space comfort and better efficiency.

CAV Systems: Ventilation Control

All CAV systems are very similar when it comes to ventilation control. The outdoor air intake shall be designed according to the application to meet the minimum ventilation airflow as per ASHRAE® Standard 62.1. Since the air volume is constant, the outdoor air intake can be controlled through a fixed damper or a motorized damper that opens when the unit is in operation and closes otherwise.

After the unit startup, a test and balance shall be performed to determine the right outside air damper position that will ensure the proper outdoor air intake. Regular maintenance is recommended to ensure that the damper remains operational.

CAV Systems Comparison

Understanding the different types of constant air volume systems, how they work, the applications they are more suitable for, and the costs associated with their implementation can provide a complete picture to engineers to properly select a type of constant air volume system that is more cost-effective for the underlying application.

Space Comfort Applications Comparison

The table below summarizes the HVAC applications for which the different types of CAV systems are most suitable.

| Application | Single Duct | Terminal Reheat | Mixed Air |

|---|---|---|---|

| Single-Zone | ✓ | N/A | N/A |

| Multi-Zone | N/A | ✓ | ✓ |

Table 1. Constant Air Volume Systems – Comfort Applications

Single duct systems are more suitable for single-zone HVAC applications such as warehouses, restaurants, residential settings, etc., while the terminal reheat and mixed air systems are more effective for multi-zone HVAC applications such as gyms, office buildings, schools, and other applications that require comfort in specific rooms.

Cost and Efficiency Considerations

The table below compares the different CAV systems based on their implementation and efficiency cost, as well as the control complexity of each system and the comfort level that can be expected.

| Metrics | Single Duct | Terminal Reheat | Mixed Air |

|---|---|---|---|

| System Cost | Normal | High | Higher |

| Control Complexity | Normal | High | High |

| Inefficiency Cost | Normal | Higher | High |

| Comfort Expected | Good | Good | Fair |

Table 2. Constant Air Volume Systems Comparison

Implemention Cost

When it comes to system implementation cost, the mixed air system is definitely the more costly of the three. This is because this system not only requires individual mixing air boxes for each room but also requires two supply air ducts and therefore a larger blower fan wheel and motor to provide air to both ducts simultaneously.

Control Complexity

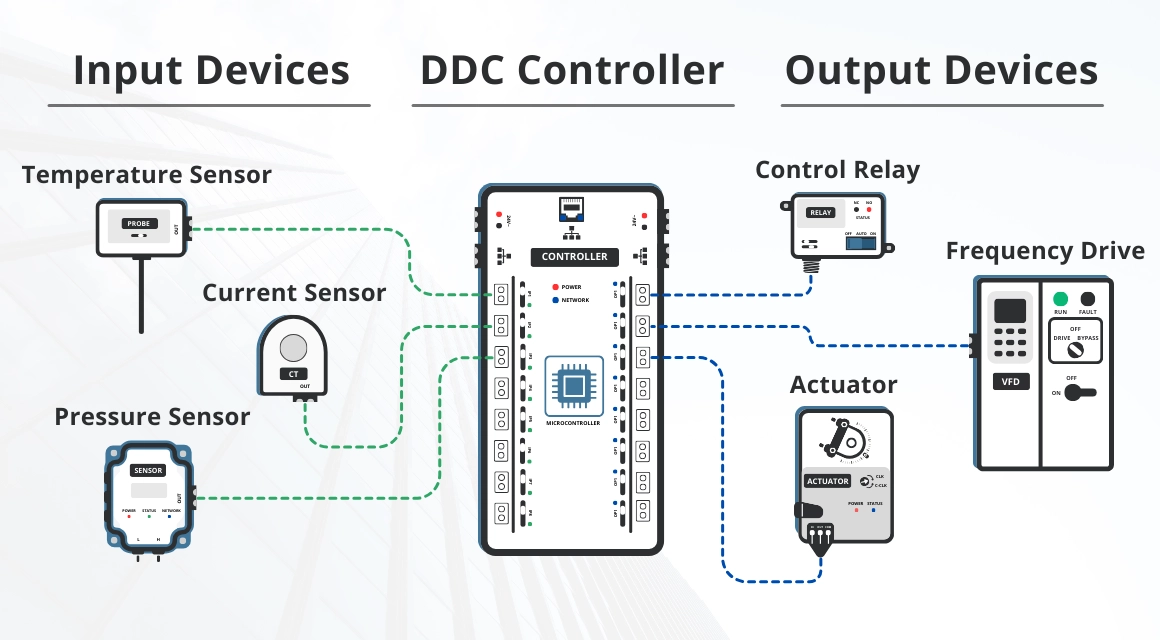

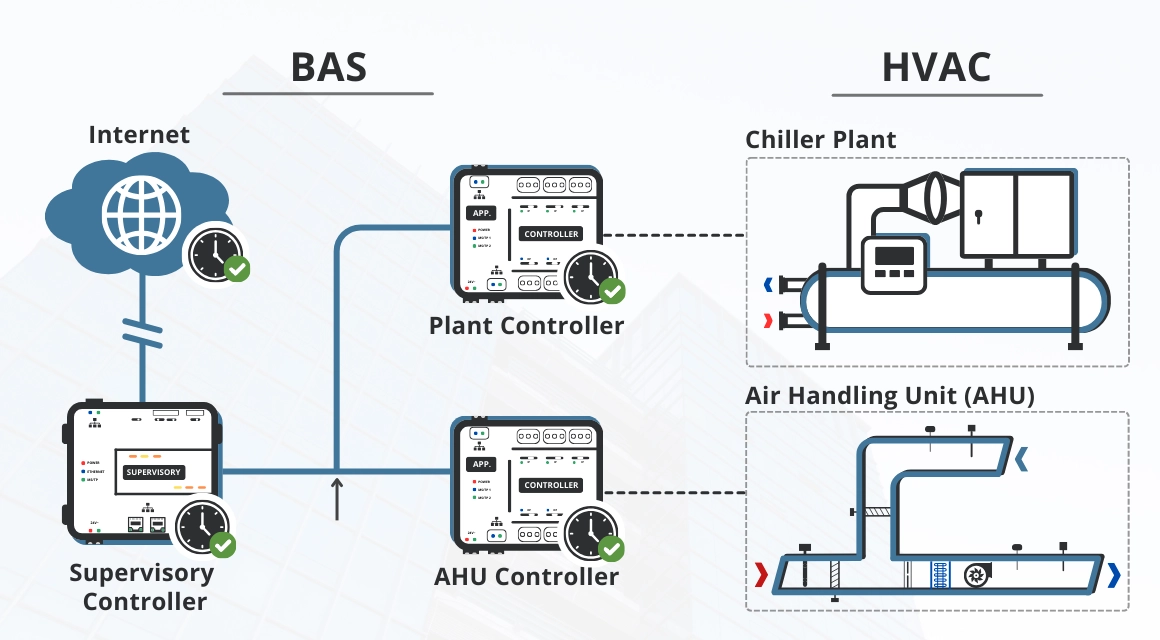

From the control complexity standpoint, we can say that both the terminal and mixed air systems are more complex in nature. These systems are very likely to require direct digital controls (DDC), which, even though they can significantly improve the efficiency of the overall system through the implementation of reset sequences, can be complex and will require expertise in the field (DDC controls) to get them properly set up.

Inefficiency Cost

Inefficiency cost is the cost differential that will be paid throughout the entire lifespan of equipment due to inefficiencies compared to a more efficient solution. The most inefficient of the CAV systems is the terminal reheat application, mainly because the reheat device needs to heat up the cold air provided by the air handling unit (AHU) when the space requires heating. This translates into a lot of energy waste in the process of reaching space comfort in this constant air volume application.

Comfort Expected

In the end, the main reason for the implementation of HVAC applications such as CAV systems is to provide comfort to the occupants. If we define comfort as temperature and humidity levels that are comfortable for most occupants in the space, we can then say that all the CAV systems reach acceptable levels of space comfort. However, mixed air systems fall short when it comes to controlling humidity for all space load conditions; that’s the efficiency-comfort trade-off engineers must consider when choosing this application.

In Summary

Constant air volume (CAV) systems are a type of heating, ventilating, and air conditioning (HVAC) application. They operate by maintaining consistent airflow while adjusting discharge air temperature to meet varying space loads. The three main types of CAV systems: Single Duct, Terminal Reheat, and Mixed Air cater to different space comfort applications.

Understanding the components, operation sequences, and efficiency considerations of these systems is crucial for informed decision-making. While single duct systems are simpler and cost-effective for single-zone use, terminal reheat, and mixed air systems are more suitable for multi-zone environments, offering enhanced space comfort at the expense of higher costs and complexities.

In terms of efficiency, terminal reheat systems incur higher inefficiency costs due to the energy-intensive process of reheating cooled air. Meanwhile, mixed air systems, despite their effective temperature control, struggle to address humidity concerns in all load conditions.

Ultimately, the choice of a CAV system should align with the specific demands of the space it serves. Engineers must weigh factors such as system cost, control complexity, and inefficiency costs against the desired comfort levels. While mixed air systems are costlier and more complex, the trade-off between efficiency and comfort is a critical consideration. As variable air volume systems gain popularity for both single-zone and multi-zone applications, the industry continues to evolve, emphasizing the ongoing pursuit of HVAC solutions that balance efficiency, cost-effectiveness, and occupant comfort.