A Building Automation System (BAS) is commonly used in the Heating, Ventilation, and Air Conditioning (HVAC) industry to describe the network of devices responsible for controlling the HVAC equipment and systems in large facilities and commercial buildings.

Mechanical systems typically require some form of control to operate as intended, and this is also true for HVAC equipment. The most basic HVAC control is a thermostat, which drives the HVAC equipment to maintain the desired temperature setpoint. However, commercial HVAC applications are more complex and require more than just a basic thermostatic sequence to operate. This is why a network of controlling and supervisory devices, known as the Building Automation System (BAS), is used.

Implementing a BAS also enables additional benefits that are not possible through a simple standalone thermostat, such as control synchrony, remote supervision, energy management and efficiency, fault detection, system integration, and data analytics. In the rest of this article, we will go over each of these benefits.

BAS and HVAC Control Synchrony

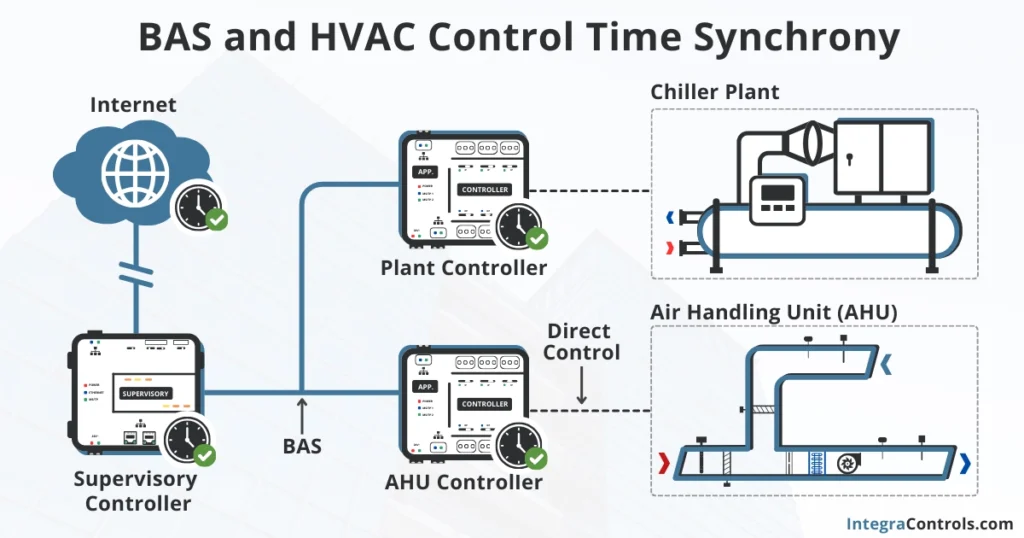

HVAC control synchrony refers to the capability of HVAC equipment to be synchronized in time. In campuses, buildings, and large facilities, there are multiple HVAC units spread out around the premises, and they all have an internal time clock that must match each other to enable effective management.

Importance of Time Synchrony in HVAC

HVAC systems in large facilities are typically managed by building operators and engineers through occupancy schedules, which are set based on building and zone occupancies to save energy during unoccupied periods. This is why time synchrony is so important. It would not be possible to control the HVAC system through schedules if HVAC controllers did not share the same time clock. This is where the BAS network plays a critical role.

It is through the BAS network that time synchrony across all the HVAC equipment takes place. All the devices in the network, typically DDC controllers and supervisory devices, share a common time clock thanks to the building automation network. This occurs through broadcasting protocols set at specific intervals. The supervisory controller is normally the master broadcaster, gathering the time data from the internet and sharing it with the rest of the devices in the network, ensuring the effectiveness of occupancy schedule control.

BAS, BMS, and HVAC Remote Supervision

In residential homes, HVAC equipment is normally set and managed by tenants and homeowners, setting temperature setpoints and runtime periods at will. But who manages the HVAC system in large facilities?

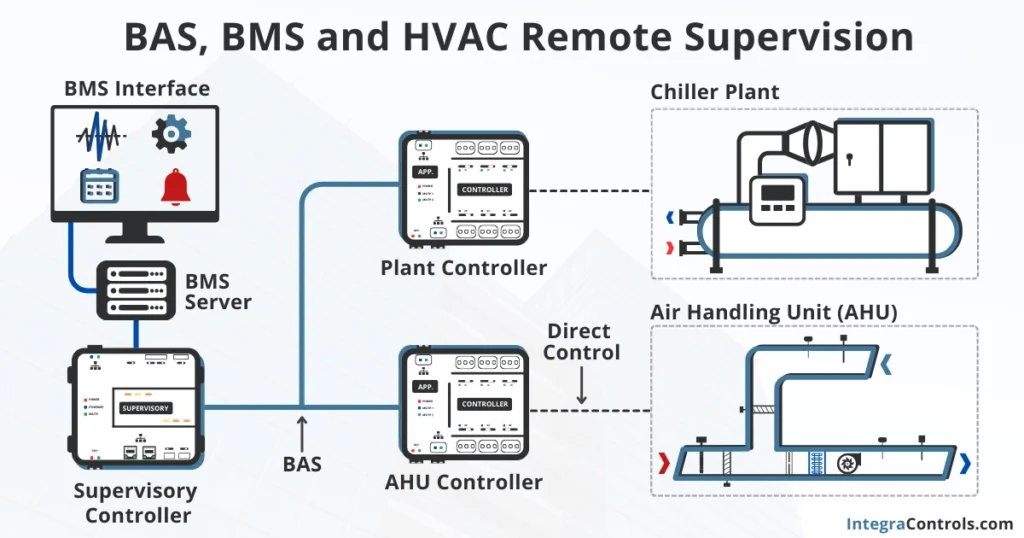

As mentioned earlier, in commercial applications there are personnel dedicated to managing, supervising, and setting up the HVAC system, as well as making sure it is properly maintained. This is the job of facility managers, engineers, and operators. However, in large commercial buildings, there might be dozens or even hundreds of HVAC units. How is it possible to manage so many units at the same time? That is possible thanks to remote control and supervision enabled through the BAS network.

Building operators typically use a front-end user interface known as a Building Management System (BMS). This interface provides real-time visual information on the HVAC system’s performance, alarms, and trends. The BMS also provides remote control over the equipment, allowing operators to change setpoints, occupancy schedules, and override the unit’s operation.

The BMS shows the information shared inside the BAS network. It is through the BAS network that the data is captured and sent to the BMS front-end interface so the operators can remotely visualize and manage the HVAC system across multiple facilities. The terms BMS and BAS are often used interchangeably in the HVAC industry, but in reality, they are two separate systems that interact with each other.

BAS and HVAC Energy Management and Efficiency

Assuming the HVAC equipment has no operational issues and is properly maintained, there is only one way to reduce the power consumption of HVAC equipment: have the HVAC equipment work less. This is accomplished through energy management practices and by improving the HVAC energy efficiency performance through optimization strategies.

What is HVAC energy management?

HVAC energy management refers to the practices performed by facilities operators to reduce energy waste of the HVAC equipment. The most typical energy management strategies in the commercial HVAC industry are:

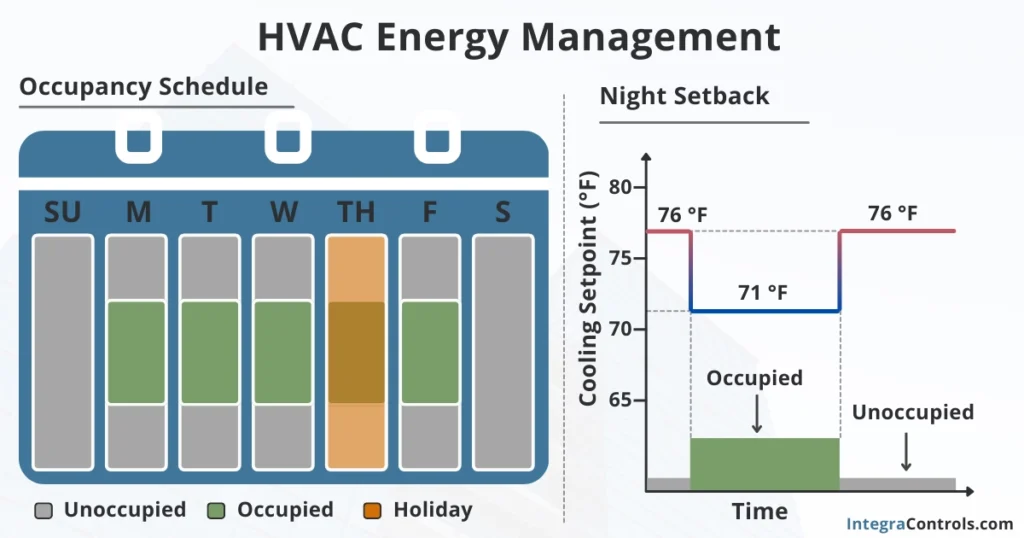

Occupancy Schedules: Operators set schedules to run or stop the HVAC units based on building and zone occupancies.

Night Setbacks: Operators establish setback temperature setpoints so that the HVAC equipment slows down at night.

Holiday Overrides: Operators set holiday calendar events that will override the HVAC operation to unoccupied mode.

All these operations are normally programmed in the HVAC controllers and supervisory devices. The operators use the BMS to interface with the HVAC equipment. The BMS delivers this information through the BAS network. Without a BAS, energy management would not be possible, and the HVAC equipment would run non-stop, leading to energy waste.

Energy management strategies are well-known by facilities operators. However, that’s not always the case for energy efficiency strategies. Few people are aware of them, and more than 90% of facilities don’t have them implemented simply because they are unaware.

What are HVAC energy efficiency strategies?

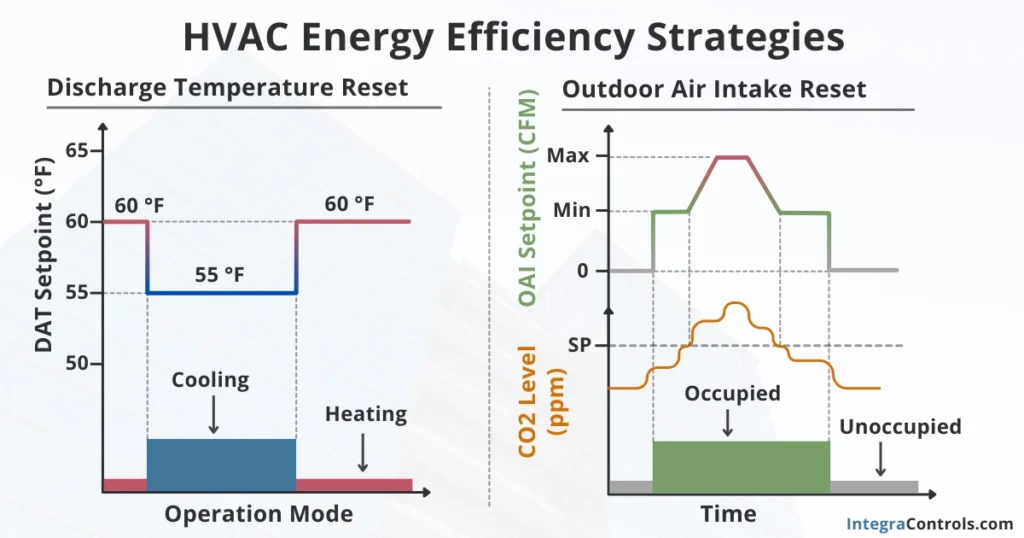

Energy efficiency strategies are programmed optimization sequences that reduce the overall base power demand and power consumption of the HVAC equipment by resetting the HVAC operational setpoints based on demand response. There are many energy optimization sequences that can significantly improve the overall operational efficiency of HVAC systems. The most effective ones include:

Discharge Air Temperature Setpoint Reset: Based on humidity override or space load demand, the discharge air temperature setpoint can reset lower or higher to maintain space comfort while reducing energy consumption.

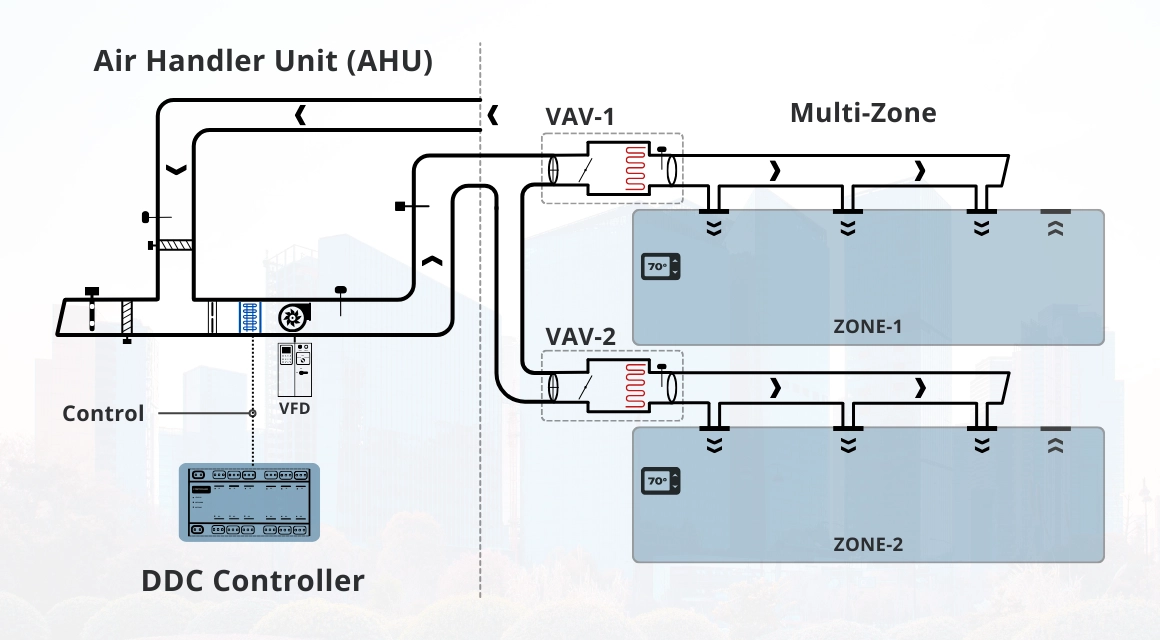

Duct Static Pressure Setpoint Reset: This optimization is more commonly used in multizone variable air volume (VAV) applications. The duct static pressure setpoint can reset higher or lower based on the airflow demand of the VAV boxes serving the space.

Outdoor Air Intake Setpoint Reset: This sequence allows the outside air setpoint to reset higher or lower depending on space occupancy demand and carbon dioxide levels. This sequence is also referred to as controlled demand ventilation.

Energy optimization strategies are extremely effective in eliminating energy waste and driving energy savings. In fact, HVAC systems using these sequences often consume less than half of what they were consuming prior to their implementation. Unfortunately, most facility managers and operators are not aware of these energy efficiency optimization strategies. Additionally, it requires in-depth knowledge of HVAC control operations and programming to set them up effectively.

Energy efficiency strategies use data exchange from the HVAC controllers and supervisory devices to drive optimization decisions. This data is transmitted through the BAS network. Without a BAS, it would not be possible to optimize the HVAC system operation and maximize energy efficiency.

BAS Role in HVAC Fault Detection

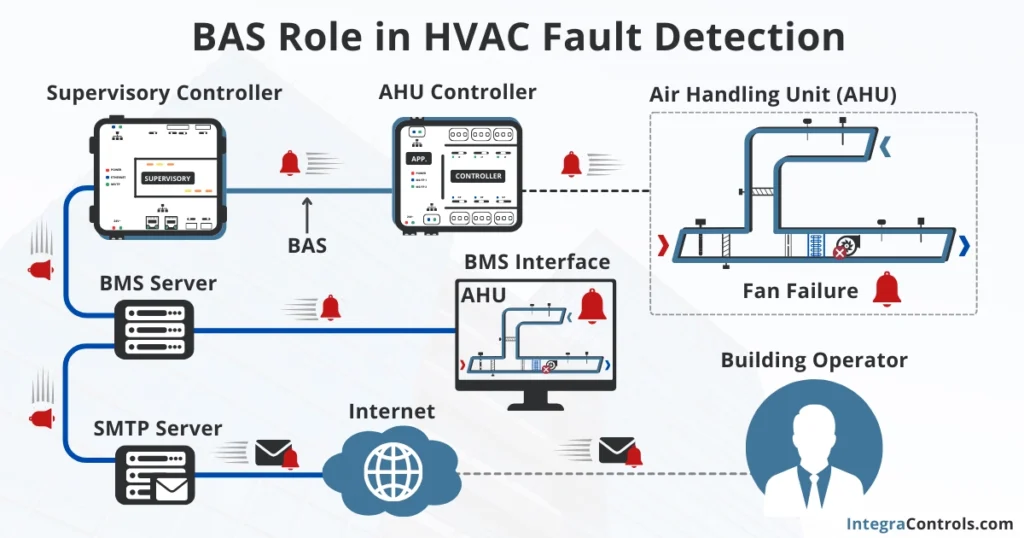

One of the many benefits of remotely supervising the HVAC system through a BMS front-end interface is the capability of visualizing the system’s alarms and faults generated by the controllers in the BAS network.

Fault detection algorithms are typically set inside the controller and supervisory devices. When an HVAC fault is detected by a controller, it will generate an alarm event. The alarm event is transmitted into the BAS network until it reaches the supervisory device and BMS host. This way, the event can show on the BMS interface for operators to visualize, and it is also typically sent via email to the designated users.

The BAS plays a crucial role in fault detection and routing. A standalone controller not connected to the BAS network can detect HVAC faults, but no one will know about them.

Properly planned and curated fault detection algorithms can put building operators ahead of the HVAC equipment failing curve, preventing complete failures and business interruptions.

BAS Integrations and HVAC Performance

BAS integrations refer to the capability of the BAS network to communicate and incorporate other monitoring and controlling devices beyond just HVAC-related controllers.

HVAC Energy Performance

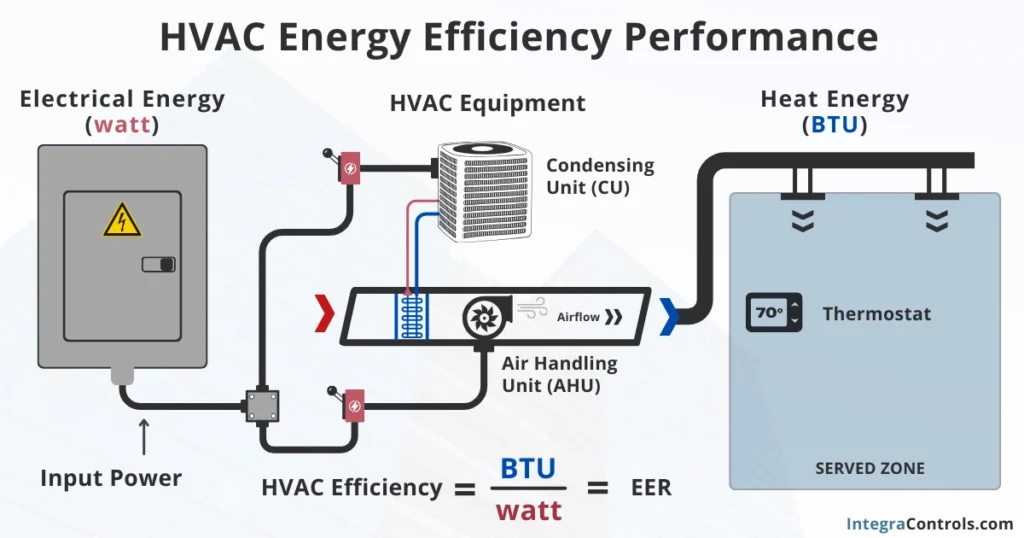

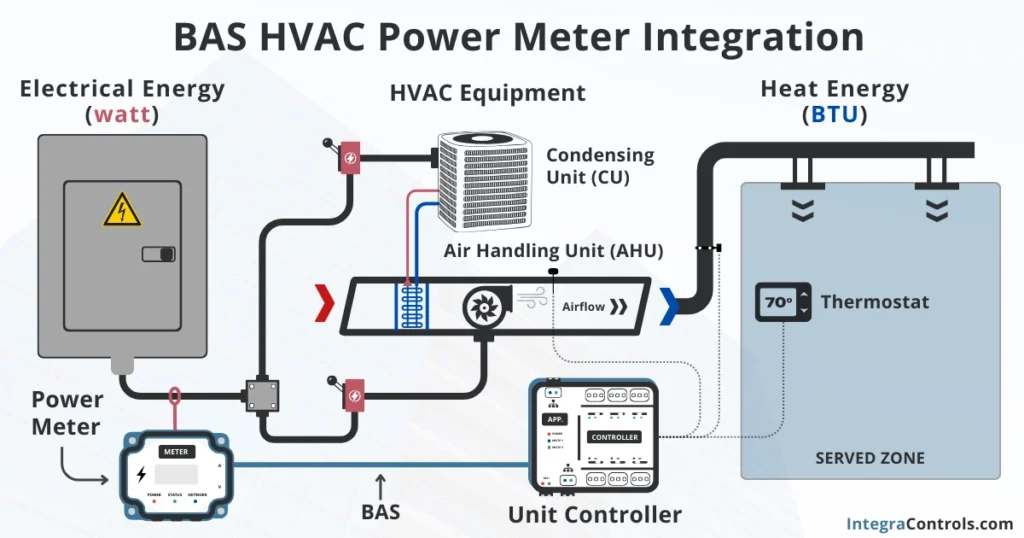

HVAC performance, like most mechanical equipment, is measured in units of output per unit of power. The unit of output for HVAC systems is the British Thermal Unit (BTU), which measures how much heat energy the HVAC system removes from (cooling) or adds to (heating) the underlying served zone.

When dividing the real-time BTU output of an HVAC equipment by the total power demand, we obtain a metric of performance known as the Energy Efficiency Ratio (EER). The higher the EER, the more efficient the HVAC unit is.

BAS Power Meters Integration

Most HVAC controllers don’t incorporate power readings. To measure HVAC performance, integrating power meters into the BAS network is a common practice. The power meters installed at the HVAC input power normally use communication protocols such as BACnet or Modbus, allowing integration into the BAS.

Through the controller monitoring sensors, we can calculate the output of the HVAC unit in BTUs. Using the power readings, the HVAC EER can be estimated. Additionally, by averaging the EER across an entire year, we can determine the unit SEER (Seasonal Energy Efficiency Ratio).

Energy performance metrics can help operators compare multiple HVAC equipment and early detect deterioration in performance due to lack of maintenance or malfunctioning components.

BAS Role in HVAC Data Analytics

The BAS network normally integrates the most energy-intensive equipment in large facilities such as chillers, boilers, cooling towers, pumps, and large HVAC units. Each equipment controller records data from sensors, actuators, and relays, which can then be archived into computer servers for data analysis. BAS is the backbone network of devices where all the data is shared and exchanged.

What is HVAC Data Analytics?

HVAC data analytics involves collecting, analyzing, and interpreting data from HVAC systems to optimize performance, improve energy efficiency, predict possible equipment failures, and ensure a comfortable indoor environment for uninterrupted business operations.

There are three main advantages that can be obtained from analyzing HVAC data:

Descriptive Analytics: Understanding current and historical system performance. Through historical trend analysis, building operators can visualize the system operation performance in real-time and compare past performance with the current one. Changes in system performance trends can indicate maintenance requirements or faulty components, allowing operators to stay ahead of equipment failure and avoid business operation interruptions.

Predictive Analytics: Forecasting future performance and potential issues. Analytic algorithms can process large amounts of data and arrive at forecasting conclusions. This information is then used to prescribe solutions and system adjustments to maximize HVAC performance and efficiency.

Prescriptive Analytics: Recommending actions to optimize system performance. As mentioned earlier, once an analytic algorithm generates forecasting data, this data is shown to the operators as recommendations to maximize HVAC performance. In other instances, operators might choose to allow the algorithms to automatically change the system variables and operational setpoints for more efficient operation.

HVAC Data Analytics Benefits

Energy Efficiency

- Reducing energy consumption by optimizing HVAC operations.

- Identifying inefficiencies and areas for improvement.

Predictive Maintenance

- Predicting equipment failures before they occur.

- Reducing downtime and maintenance costs.

Comfort and Indoor Air Quality

- Maintaining optimal indoor conditions.

- Ensuring a healthy environment for occupants.

Cost Savings

- Lowering utility bills through efficient energy use.

- Reducing operational and maintenance expenses.

In Summary

The integration of Building Automation Systems (BAS) with Heating, Ventilation, and Air Conditioning (HVAC) systems is a transformative step toward more efficient, sustainable, and manageable building operations. The ability to synchronize HVAC controls, supervise operations remotely, implement energy management strategies, detect faults proactively, and utilize data analytics marks a new era in building management.

BAS provides a robust framework that not only enhances the performance and efficiency of HVAC systems but also contributes to significant cost savings and improved indoor air quality. Facility managers and engineers who leverage BAS can achieve greater control over their HVAC systems, reduce energy consumption, and preemptively address potential issues before they escalate into costly repairs or system failures.