Application

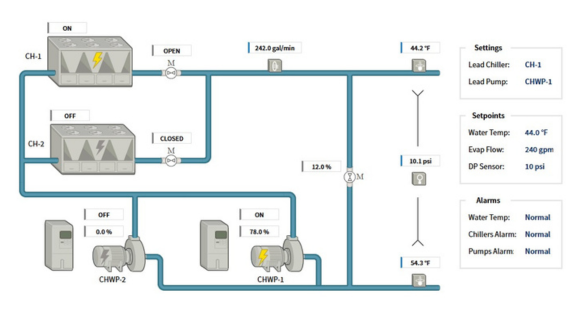

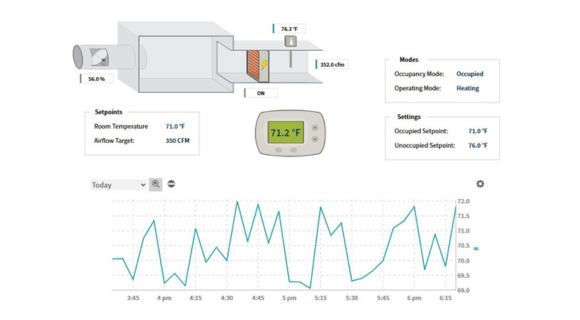

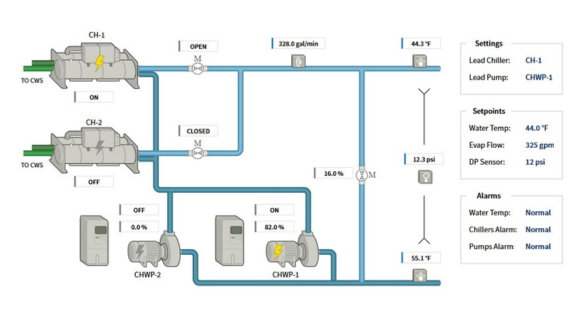

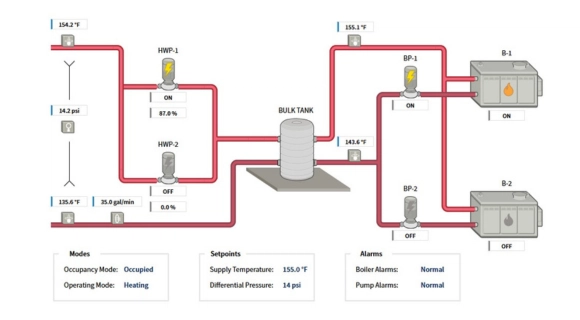

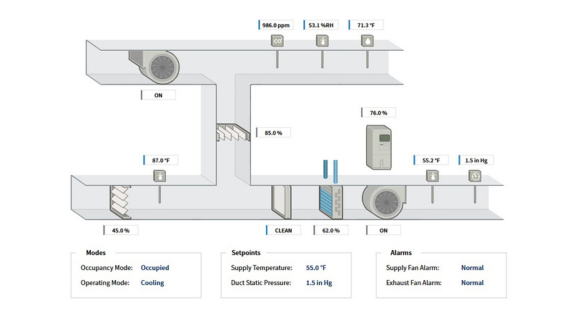

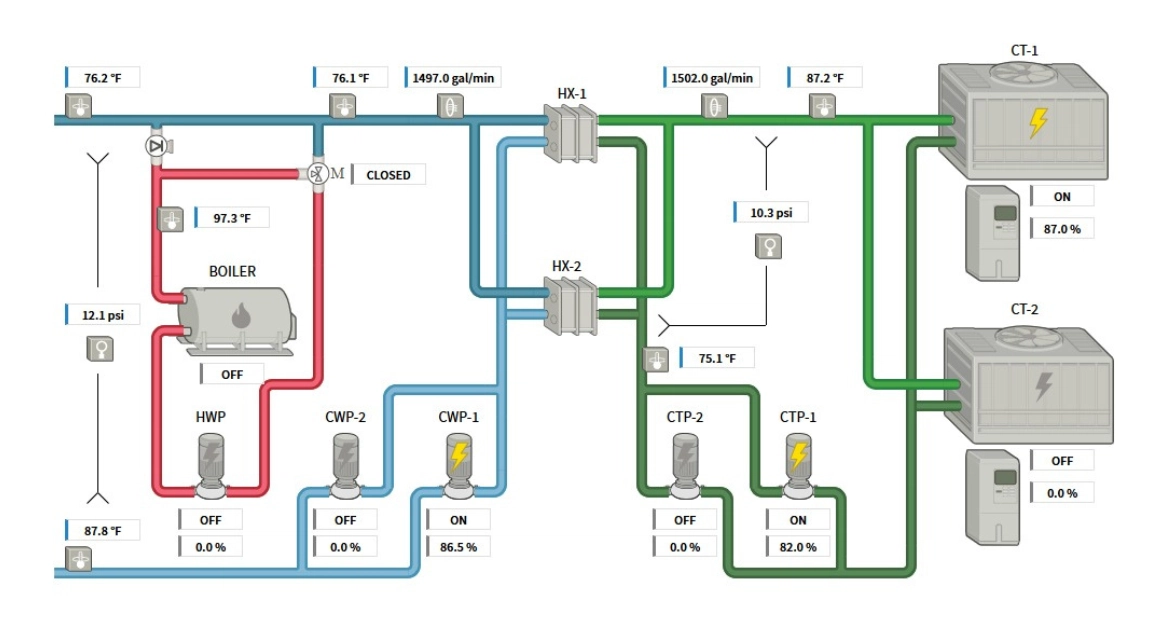

Water Source Heat Pump (WSHP) systems serve individual zones through distributed heat pumps, all connected to a shared water loop. The central plant, comprising boilers, cooling towers, heat exchangers and water pumps, regulates the loop temperature to support efficient operation.

This setup is commonly found in high-rise buildings, offices, schools, hotels, and mixed-use developments where independent zone control and centralized energy management are both required.

Without a clear interface for the central plant, operators often struggle to maintain proper loop conditions, leading to performance issues across the entire system.

User Interface Benefits

Monitor loop temperature, flow, and plant equipment status in real time: This helps ensure stable operation across all connected zones and supports energy-efficient system balance.

Coordinate boiler, tower, and pump staging intelligently: Optimizing equipment sequencing reduces energy consumption and prevents short cycling that can shorten equipment lifespan.

Track system alarms and performance trends clearly: Early visibility into deviations or faults allows for faster response and reduces the risk of widespread comfort complaints or system downtime.

Takeaways

A centralized, user-friendly interface is essential for managing the core components of a WSHP system. It gives operators the insight they need to maintain proper loop conditions, extend equipment life, and improve the performance of all downstream terminal units. With better coordination of central plant assets, buildings achieve greater comfort and efficiency with fewer disruptions.

Looking to Implement Smarter Control for your HVAC Plant Equipment?

We design BMS interfaces that simplify central HVAC plant control and help you maintain optimal performance.