Static pressure in HVAC refers to the airflow resistance that the AC unit components (filters, coils, dampers) and the air distribution system (ductwork, air vents, and grilles) exert on the blower fan’s capacity to move air through the system. High levels of static pressure typically result in low airflow volume due to clogged system components (filters, coils, vents). Conversely, low levels of static pressure can also indicate low airflow values due to air leaks or dirty blower blades.

Changes in static pressure affect the performance of HVAC systems, resulting in lower cooling and heating capacity, decreased air quality, and higher power consumption.

Pressure Readings in HVAC Systems

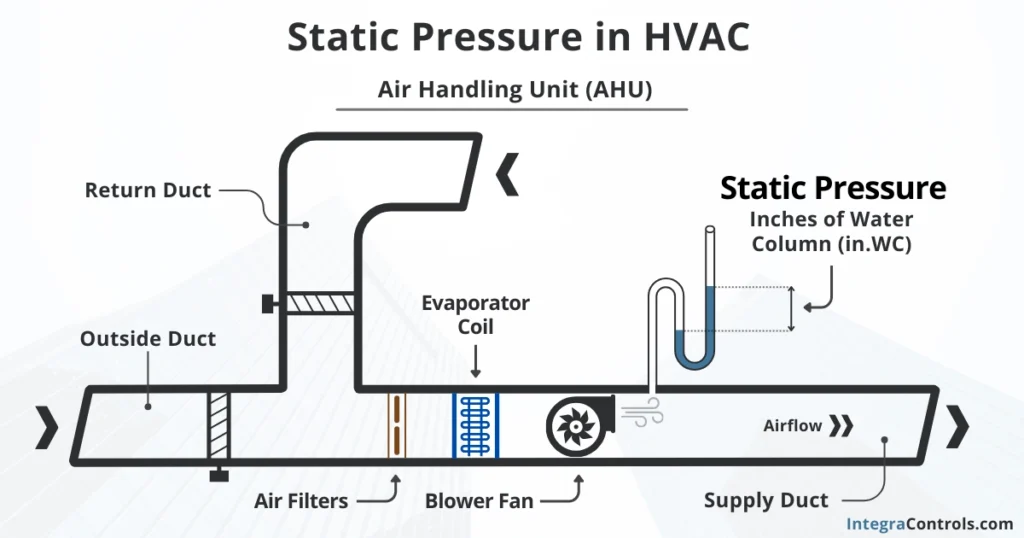

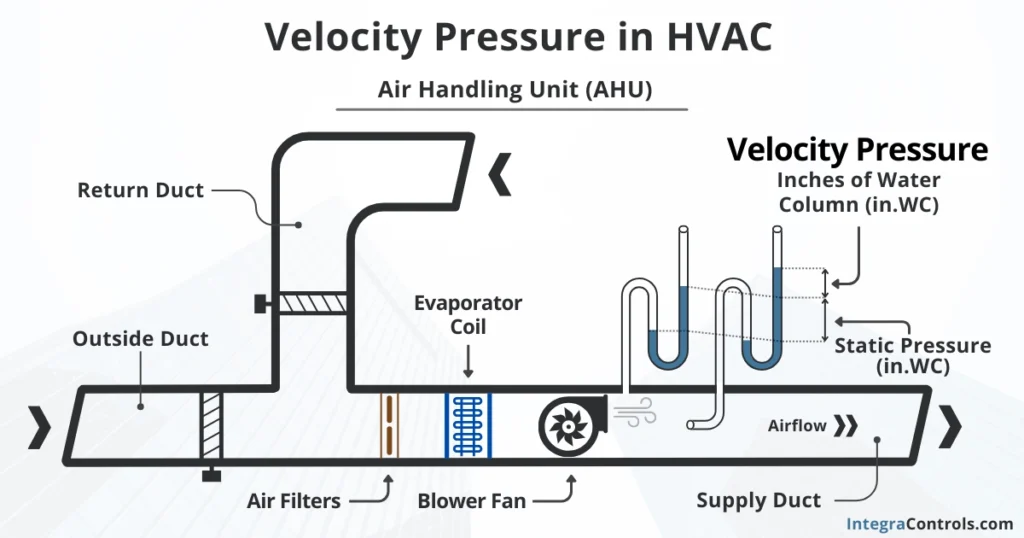

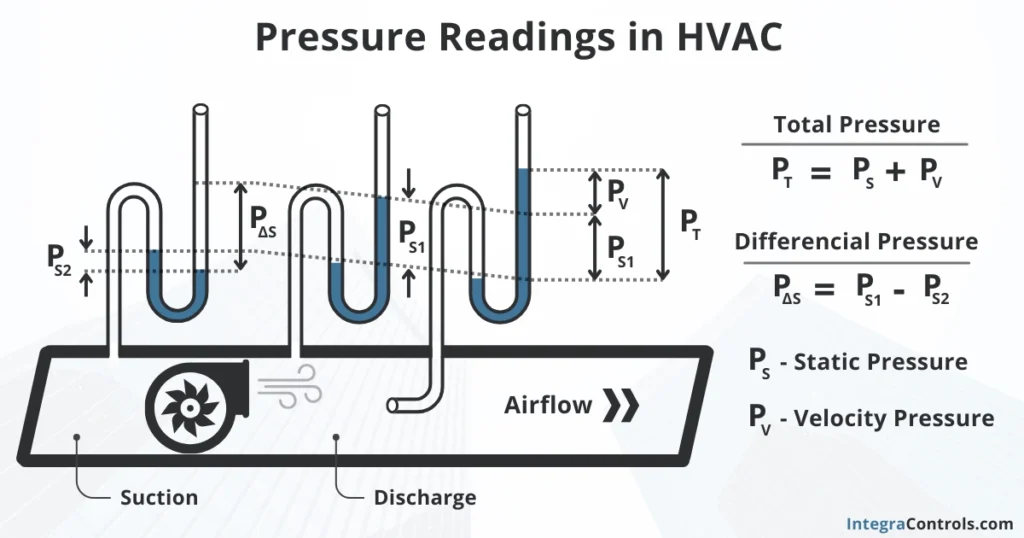

When air moves in an air distribution system, two main pressure components come into play: static pressure and velocity pressure, which together result in total pressure. The difference in pressure readings between two points is known as differential pressure.

Static Pressure

Static pressure is the pressure force the air exerts in all directions within the ductwork due to the airflow resistance the system imposes. In other words, static pressure exists because of the system’s resistance to air movement; if there were no resistance, the static pressure would be zero.

The unit of pressure in the International System of Units (SI) is the Pascal (Pa). However, in HVAC applications, static pressure is commonly measured in inches of water column (in.WC) for low pressures and air-side readings, and pounds per square inch (psi) for high pressures such as refrigerant and hydronic systems pressures.

To measure static pressure at a specific point, you can drill a small hole into the duct system and insert a pressure probe or tap connected through tubing to a pressure measuring device such as a manometer or pressure gauge. Later in this article, we will explain how to interpret different readings and changes in static pressure for HVAC systems and how they can indicate system performance deterioration.

Velocity Pressure

Velocity pressure, or dynamic pressure, is associated with air movement. It represents the force the airflow exerts in the direction of the flow, discounting the static pressure. When there is no air movement, the velocity pressure is zero.

Total Pressure

Total pressure is the pressure reading taken in the direction of the flow, considering both static and velocity pressure and it is commonly used to calculate fan total efficiency.

Differential Pressure

When we measure pressure at two different points and calculate the difference, we are estimating differential pressure, which indicates the pressure drop or airflow resistance of the segment or component we are measuring across.

Ideal Static Pressure in HVAC

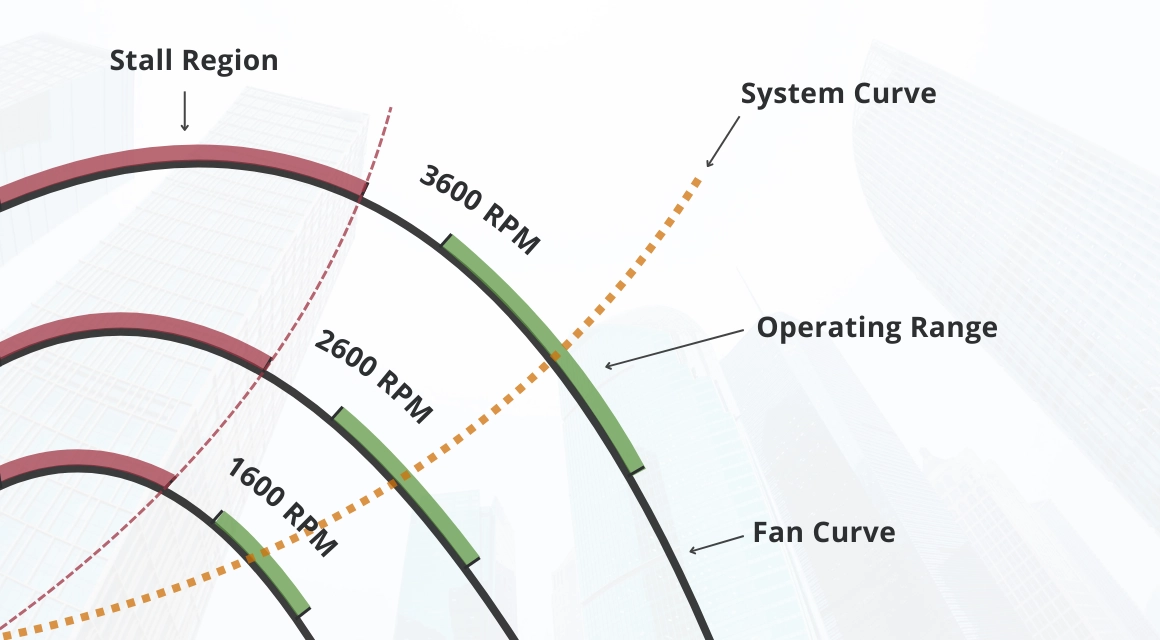

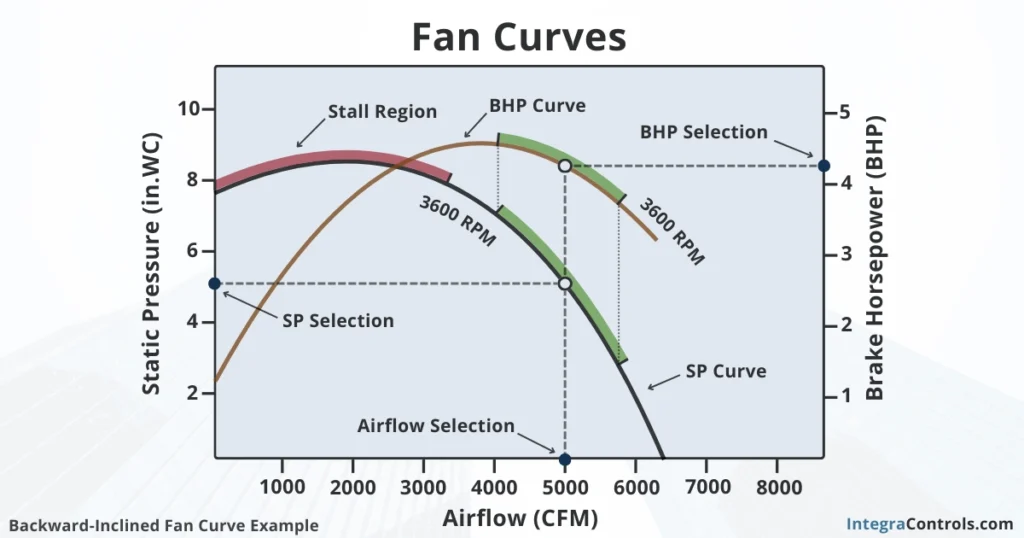

The ideal static pressure of an HVAC system depends on the final design by mechanical engineers. They estimate the static pressure of the system by adding up all the pressure drops across the AC unit and the air distribution system components. This way, engineers assess how restrictive the entire system is to airflow. This information is then used in the fan selection process and represented in the fan curves by the equipment manufacturer. To understand the performance of an HVAC system in terms of static pressure variations, we refer to the fan curves.

Fan Curves

A fan curve is a graphical representation displaying the relationship among static pressure, brake horsepower, and airflow volume for a particular fan type. The static pressure (SP) curve represents the airflow values the fan can reach for each static pressure point, while the brake horsepower (BHP) curve shows the power required to move that air, aiding in the motor selection process.

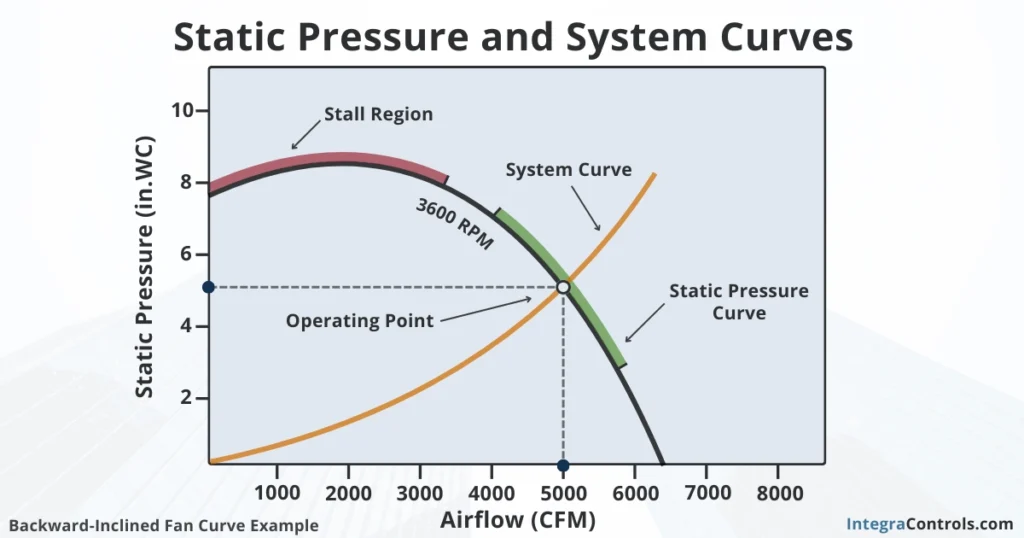

System Curve

Another important curve is the system curve. The system curve is a parabolic curve with a positive slope displaying the static pressure or airflow resistance that the air distribution system exerts at different airflow values.

As mentioned, engineers assess the total static pressure of the system and calculate the total airflow required for the application. These two determine the system operating point, which is where the fan and system curves intersect. In other words, the fan selected must overcome the total system airflow resistance to provide the design airflow for the application.

Low-Pressure and High-Pressure HVAC Systems

HVAC systems are often classified as low-pressure or high-pressure depending on the operational static pressure and air velocity values used in the application.

Low-pressure systems typically operate at static pressure levels below 2 inches of water column (in.WC). These systems, also known as low-velocity systems, require larger ductwork to transport high volumes of air and tend to be quiet. Low-pressure systems are commonly used in single-zone constant air volume (CAV) applications for residential and small commercial buildings due to their low implementation cost and noise performance.

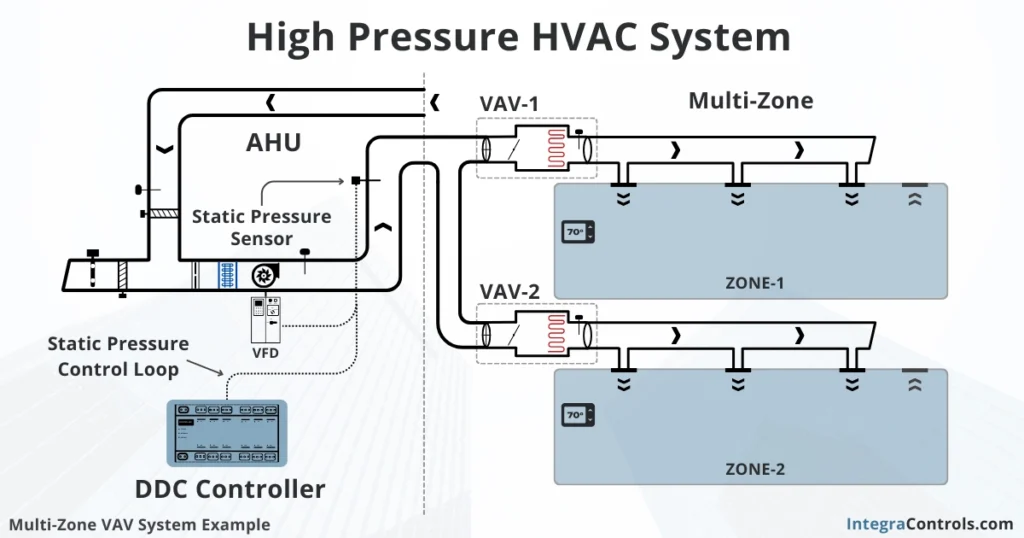

On the other hand, high-pressure or high-velocity HVAC systems operate at static pressures above 2 inches of water column (in.WC). They use smaller ductwork since the air is moved at higher velocities but tend to be noisier due to higher pressure and air turbulence. These systems are commonly used in single-zone VAV applications as well as in multi-zone VAV systems for large commercial buildings, industrial, and healthcare facilities as they provide higher levels of room comfort and efficiency.

Causes of HVAC Static Pressure Issues

Undersized Air Returns

The total static pressure of the system decreases due to undersized returns, as the blower fan has to work harder to pull the air. In extreme cases, a fully closed return can cause the fan to rotate without moving any air.

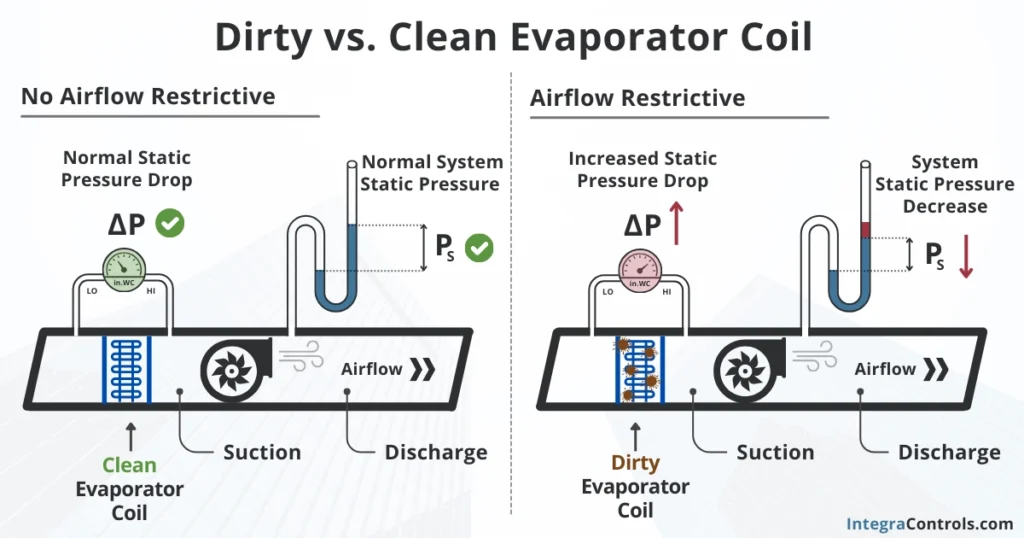

Dirty Evaporator Coils

When cooling or heating coils are dirty, they typically cause the static pressure to drop, making it harder for the unit to move air.

Clogged or Too Restrictive Air Filters

Clogged air filters or those with higher filtration ratings lead to static pressure decreases, restricting the capacity of the fan to move air through the entire system.

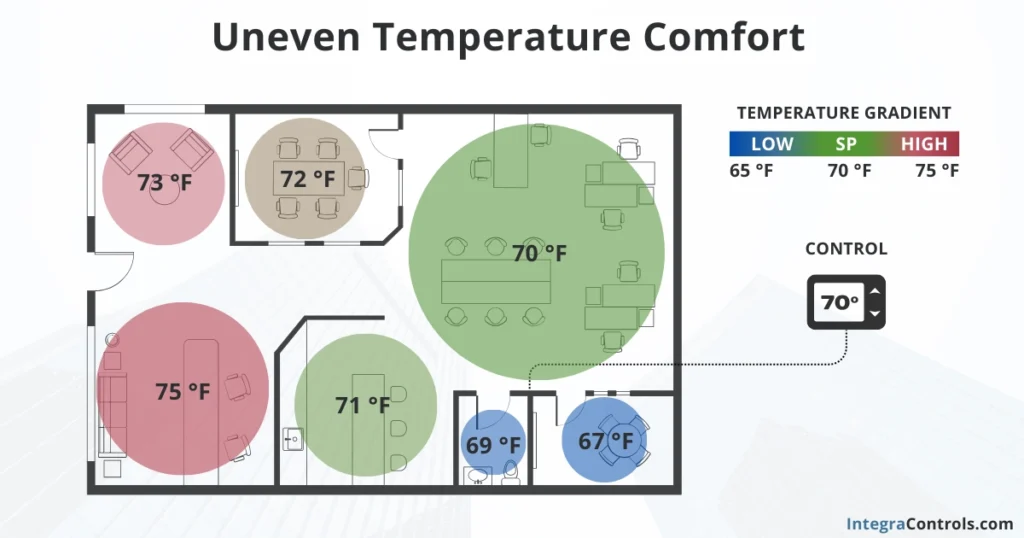

Incorrectly Sized HVAC Equipment

Undersized HVAC equipment causes static pressure and total airflow to be lower, leading to room temperature discomfort. Oversized HVAC equipment typically produces higher static pressure values, leading to increased noise, room humidity and temperature discomfort, compressor short cycling, and possible damage to the overall system.

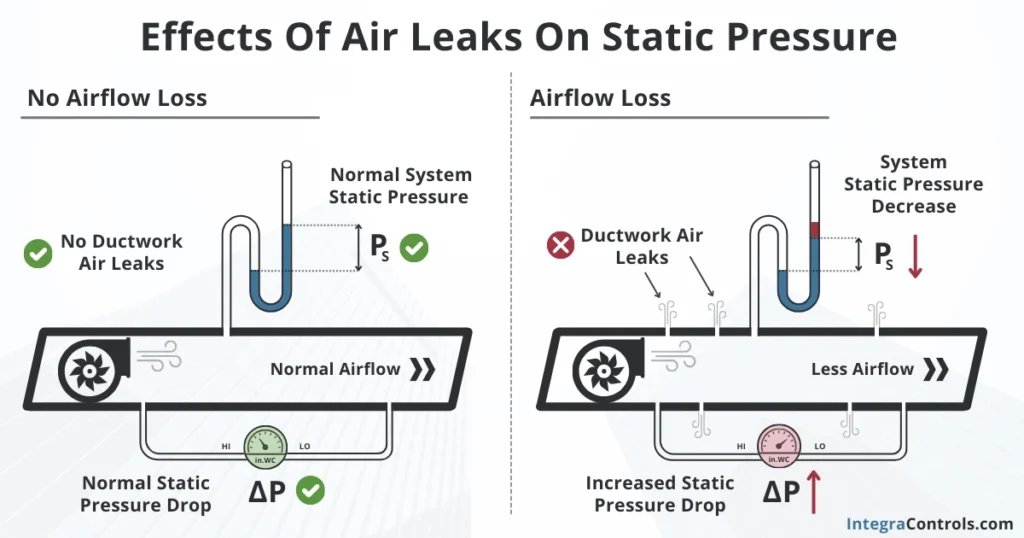

Leaky Ductwork

Duct static pressure drops as a result of air leaks in the air distribution system, leading to poor energy efficiency performance, undesired condensation spots, and higher energy bills.

Improper Ductwork Design

Improper ductwork design, such as incorrect duct sizing, sharp bends and turns, improper air vents, and filter ratings, affects overall system static pressure when calculations are not done properly, and field conditions have not been properly considered.

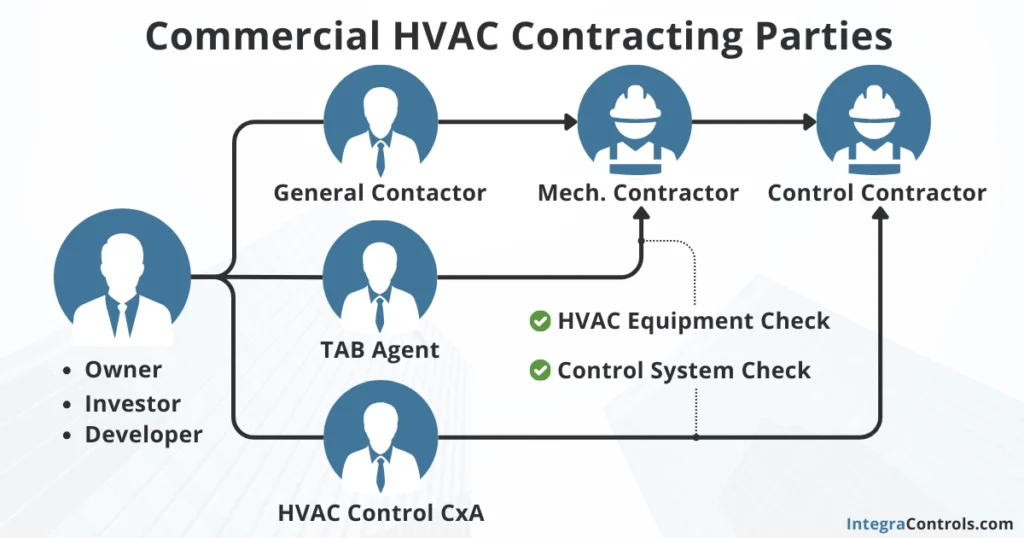

Lack of Testing, Adjusting, and Balancing

In commercial HVAC applications, a testing, adjusting, and balancing (TAB) vendor is typically hired by the owner to ensure the HVAC system is properly installed, sealed, adjusted, and calibrated according to design intent, including proper operation of static pressure levels. If TAB is not performed properly, the system performance can be extremely poor, leading to continuous failures and inefficiencies.

Lack of Control Commissioning

Similar to the TAB vendor, a commissioning agent or CxA ensures the HVAC control system works as intended. This is more common in large commercial applications with a building automation system (BAS). Commercial HVAC control systems are complex and require experts to set them up and inspect them properly. Non-commissioned HVAC control systems are one of the most common reasons for energy waste in commercial buildings, with improper static pressure setups being a major factor.

Signs of HVAC Static Pressure Problems

Increased Noise Levels in the System

When an HVAC system produces excessive noise, it might indicate an increase in static pressure. As the fan speed remains constant, static pressure increases typically lead to higher air velocity values, resulting in loud noises such as whistling, whirring, or humming.

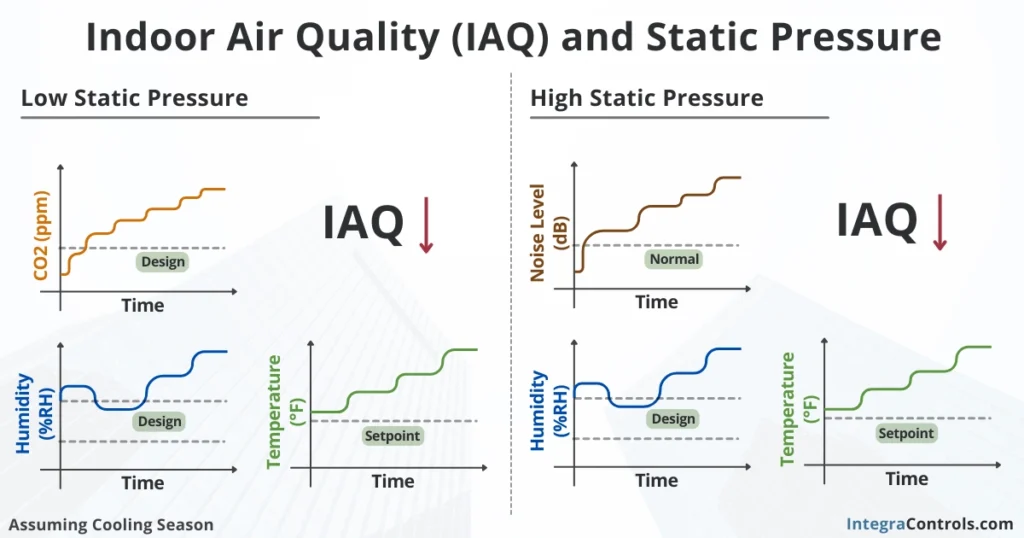

Decreased Indoor Air Quality

Changes in the HVAC system’s static pressure can affect indoor air quality (IAQ) by negatively influencing factors such as temperature, humidity, and ventilation. Static pressure issues cause air imbalances and distribution problems, creating temperature differences across served zones.

Relative humidity typically rises due to increases in static pressure as it affects the heat exchange efficiency of the evaporator coils. On the other hand, ventilation may decrease at lower-than-normal static pressure values, leading to high carbon dioxide (CO2) levels, causing headaches, fatigue, nausea, lack of concentration, and other discomforts.

Higher Energy Bills

Almost 20% of the total average U.S. home power bill is due to the HVAC system, while in commercial buildings this number is around 35%. Higher than expected power bills might indicate that the HVAC system is working harder than usual, which could hint at static pressure issues. Both increases and decreases in static pressure can cause energy waste and higher power bills.

Effects of High Static Pressure

Reduced System Efficiency

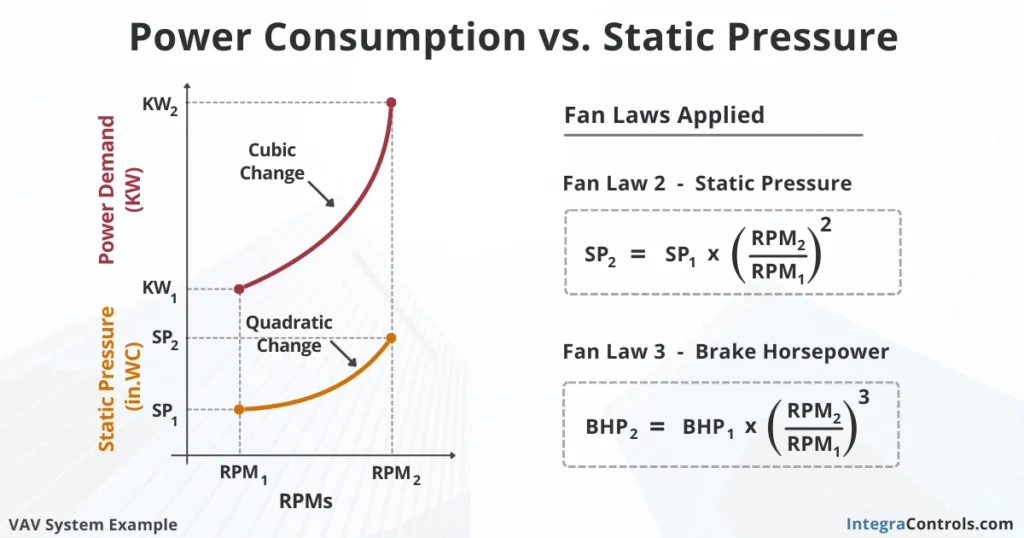

Increases in HVAC static pressures typically result in higher bills and energy waste. In constant air volume systems, where the fan revolutions per minute (rpm) are fixed, increases in static pressure normally indicate that supply-side air distribution ductwork has become more restrictive to air movement, causing the total airflow of the system to decrease. Therefore, the AC unit has to work for longer periods to achieve the same temperature comfort.

In single-zone variable air volume systems, the fan’s speed changes on demand. As the air distribution system becomes more restrictive due to higher static pressure, the fan blower motor RPMs must increase to maintain the same level of space comfort, leading to higher power consumption.

Similarly, in multi-zone variable air volume systems, the fan RPMs are also variable and controlled through static pressure compensation mechanisms. Generally, the higher the static pressure setpoint, the more energy the fan motor consumes. An improperly set static pressure control setpoint is one of the most common sources of energy waste in commercial HVAC applications.

Increased Wear and Tear

Increases in static pressure typically lead to higher equipment power consumption and longer runtime. This can cause motor overheating, shortening the equipment’s lifespan, and increasing wear and tear on components such as fan belts, magnetic contactors, and transformers.

High discharge static pressures reduce airflow in the system, causing lower suction pressures that can potentially lead to coil freezing and compressor damage.

The air distribution system can also be impacted by higher-than-expected static pressure values. As the blower fan exerts more pressure on the ductwork system, the possibility of causing air leaks due to damaged ductwork seals increases.

Effects of Low Static Pressure

Temperature Discomfort

Low static pressure values usually indicate lower levels of airflow in the ductwork due to factors such as air leaks, clogged filters, or dirty cooling coils. When HVAC system airflow output decreases, so does the unit’s total capacity. This means that the rooms served can experience temperature discomfort as the AC unit struggles to meet the total heating or cooling load demanded by the served zones.

Increased Power Consumption

As mentioned earlier, low static pressure translates into reduced cooling and heating capacity, causing the AC unit to run for longer periods, leading to lower energy efficiency and higher power consumption. In pressure-compensated HVAC systems, the blower fan is forced to run at higher RPMs, resulting in similar effects.

Reduced Equipment Lifespan

Extended AC runtime periods due to low static pressure values cause wear and tear on unit components such as fan belts, magnetic contactors, and transformers, as well as fan blower motor overheating and evaporator coil freezing, shortening the overall equipment’s lifespan..

How to Prevent Static Pressure Issues

Replace Filters Regularly

Clogged air filters are one of the most common causes of low static pressure in AC systems, affecting airflow and unit capacity. Replacing the filters every 90 days is a good practice to keep the AC running smoothly while maintaining adequate indoor air quality.

Regular HVAC Maintenance

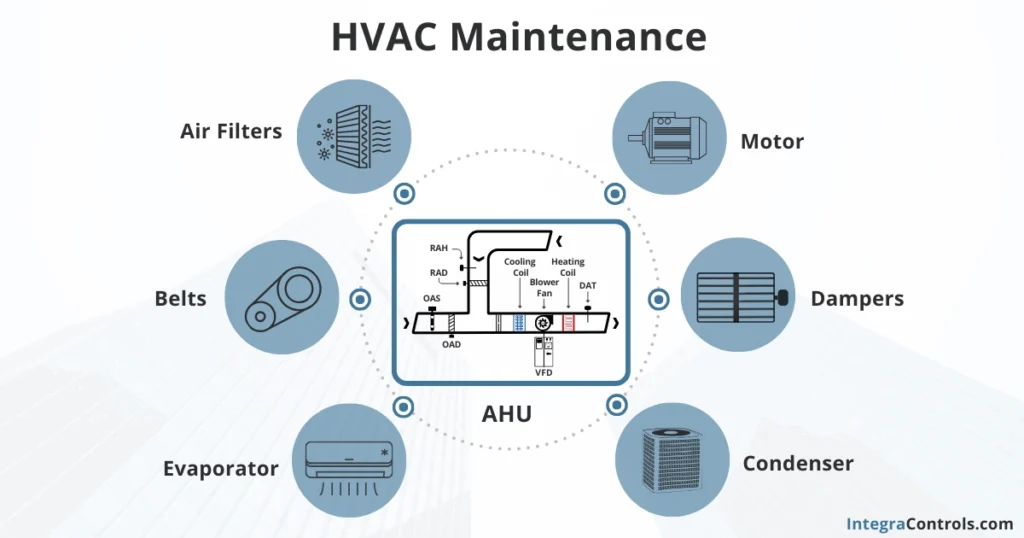

AC systems run almost continuously, and like most mechanically driven equipment, they require regular inspections and maintenance to maintain high performance. Regular maintenance, such as cleaning evaporator coils, replacing blower belts, greasing motors, tightening loose components, and dusting return grilles and supply vents, can prevent many static pressure issues. Additionally, taking static pressure readings and differential pressure drops during maintenance can help identify performance deterioration indicators.

Sealing Leaky Ducts

Leaks in the ductwork system are a typical factor that leads to low static pressure issues, air distribution imbalances, unit capacity deterioration, uncomfortable indoor temperatures, higher motor runtimes, and increased power bills. Ensuring all air leaks are sealed can prevent these detrimental effects.

Proper Equipment Sizing and Ductwork Design

Some HVAC static pressure problems are harder to prevent, such as improper ductwork and equipment sizing, undersized motors, and inappropriate ductwork configurations. These problems occur due to errors during the design phase or poor installation practices during construction.

When an AC unit is in good condition but not performing as expected, there may be design or installation issues. In such cases, it’s recommended to seek professional assistance from an HVAC mechanical engineer or an experienced mechanical contractor to find the root of the problems.

Testing, Adjusting, and Balancing

In commercial applications, mechanical contractors typically need a clear-of-deficiencies testing, adjusting, and balancing (TAB) report to pass their final inspection. This is usually mandatory in new construction projects. However, if TAB is not performed properly, the consequences can be detrimental in terms of equipment performance, energy efficiency, and overall system lifespan. It is crucial for the TAB company to be a third-party agency hired by the developer or building owners to avoid conflicts of interest and maximize system performance.

HVAC Control Commissioning

The HVAC control system is the last piece of the puzzle in HVAC applications for commercial buildings. Commercial HVAC systems differ significantly from residential counterparts in terms of control complexity. The difference is such that a separate contractor, usually referred to as an HVAC control contractor, system integrator, BAS contractor, or control vendor, is required.

HVAC control contractors are responsible for furnishing, installing, programming, and commissioning the HVAC control equipment, typically DDC controllers. They also connect all these control devices into a network known as the building automation system (BAS) and create a user interface application for the building operator referred to as the building management system (BMS).

However, similar to the TAB company, it’s recommended that building owners or developers hire a third-party HVAC control commissioner, referred to as a commissioning agent or CxA, to ensure that the HVAC control system is working as per design. Proper HVAC control commissioning can help avoid HVAC energy waste, improve system performance, and extend equipment lifespan.

In Summary

Understanding and managing static pressure in HVAC systems is crucial for maintaining optimal performance, energy efficiency, and indoor air quality. Static pressure issues can lead to increased energy consumption, system inefficiencies, and equipment wear and tear. Regular monitoring and maintenance can prevent static pressure problems and ensure the longevity and efficiency of the HVAC system. Proper HVAC static pressure levels not only enhance comfort but also reduces operational costs and promotes a healthier indoor environment.